Beechcraft Model 200 King Air

Chafing Wing Bolt Cover

During a scheduled wing bolt inspection, the left lower aft bathtub fitting was found to have chafe marks from contact with the clip on the wing fitting cover. One mark extended into the fitting radius. The manufacturer was consulted and provided a field repair to remove the damage.

Each bathtub fitting cover is held in place by a spring-steel clip that grips the wing fitting at one end while the other end is held in place by a screw. It appears the cover may have been a little loose, allowing it to flutter or vibrate and causing the clip to chafe the wing fitting.

Part total time: Unknown

Beechcraft Model B90 King Air

Loose Wing Attach Bolts

Inspection after a turbulent air encounter discovered both upper forward wing bolts and nuts were installed only hand-tight. Wing-bolt inspection had been completed 116.8 hours earlier, and a wing bolt re-torque check had been complied with 44 hours earlier.

It appears required torque could be met, even though nuts were not fully engaged or correctly torqued to begin with, due to downward pressure exerted on wing.

Part total time: Unknown

Cessna Model 172 Skyhawk

Blocked Fuel Vents

Pilot experienced fuel interruption while en route but landed without injuries or damage. During recovery, technicians noted draining the fuel tanks with fuel caps on was slow. Removing fuel caps increased flow rate at fuel drain.

Inspection revealed fuel cap vent holes were clogged with mud, and the left wing fuel tank vent was restricted. Blowing nitrogen through the fuel vent tube cleared the blockage.

Fresh fuel was installed in each tank and the fuel caps were replaced with new units. A flight was made without incident.

Part total time: Unknown

Cirrus Design SR22

Alternate Air Door

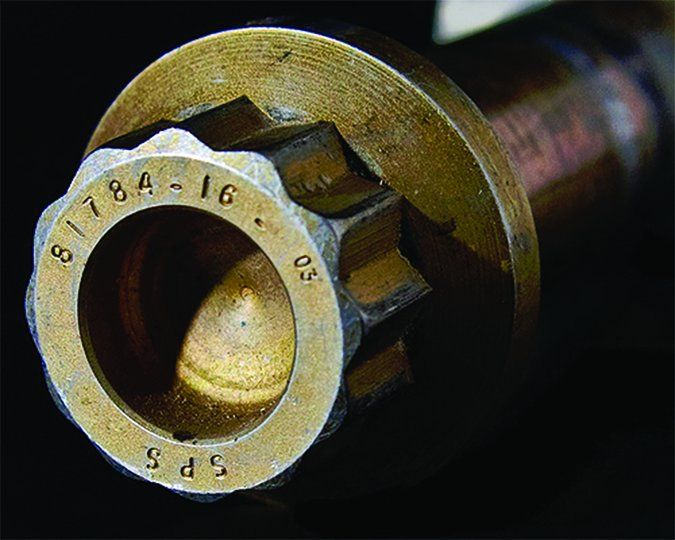

During removal and replacement of the p/n 15708-001 induction duct assembly, a crack was noted in the area of the AN3-34 bolt serving as a hinge pin for the alternate air door. The bolt was found to have a groove worn into its shank 360 degrees around.

It appears the stainless steel induction duct support bracket (p/n 15671-002) is wearing into the AN3 bolt. Other same-model aircraft in the fleet were found to have some degree of wear on bolt and similar duct assembly cracking.