Unless you’re flying a hot-air balloon, a sailplane or something with an engine that must be hand-propped, your aircraft has an electrical system. It may power only the basic equipment, like lights and the engine’s starter motor, or it can power everything, including the landing gear, flaps and flight instruments. Modern systems—and even those aboard so-called legacy aircraft—usually are relatively simple and robust, with well-understood components and maintenance requirements.

Your ground school training and some quality time with your aircraft’s reference materials will inform you on what electrical components your aircraft carries and what emergency procedures, if any, are recommended when something fails. Those materials often are heavy on procedures and light on what options may exist. A better understanding of electrical systems and their components can help you find problems during scheduled and preflight inspections, as well as fix things when they break.

Basic System Features

Aboard most personal aircraft, it’s important to separate the engine’s ignition system from the rest of the electrical system. The typical personal aircraft has a piston engine running on magnetos, which generate and coordinate the energy flowing to spark plugs. Once it’s running, its electrical operation is self-contained and does not depend on the same system used to start it.

Most general aviation aircraft operate with either a 12- or 24-volt DC system; 12 volts is more common among aircraft built before the 1980s. The basic components include a storage battery of the proper voltage supplying power for engine starting and emergency power. An engine-driven alternator or generator, plus a voltage regulator, is the primary source of electrical power. A master switch and electrical wiring connect to one or more bus bars, circuit breakers and switches supplying power to individual loads for lighting, electronics including navigation and communication radios but also primary flight instruments, pitot heat, autopilot, electric flap and retractable landing gear motors and engine starters, etc.

After completing a prestart checklist, ensuring that all switches and engine controls are in the correct position for engine start, the master switch is energized and current flows to the bus bar. When the starter is engaged, a low current flow through the starter relay energizes a heavy contact switch within the relay, allowing high current flow to the starter motor. As the engine starts, releasing the start switch de-energizes the starter motor, allowing it to disconnect and de-accelerate while the engine settles into a power setting commensurate with its controls.

Once the engine is above a certain speed, the alternator or generator supplies primary electrical power. Dedicated electrical circuitry regulates and protects the generator or alternator from overvoltage, reverse current and excessive current draw above maximum rated output. The ammeter should be monitored to identify unusual charge or discharge rates. A continuous discharge with no charge shown at high engine rpm with an electrical load applied is a good indication that the alternator/generator has failed. Check that the alternator switch is in the “on” position and if that doesn’t correct the problem, maintenance is required.

During cruise flight, it is important to include the ammeter in your normal scan, noting any trouble such as a high rate of discharge. Consideration should be given to the installation of a voltmeter or a low voltage warning light to alert the pilot of an abnormal voltage condition if your aircraft is not so equipped. Normal system voltage with engine operating in cruise flight (12-volt system) should be between 13.5 and 14.5 volts, depending on the outside air temperature. Static open circuit voltage without the generator/alternator charging the battery should be around 12.9 volts at standard temperature, indicating a fully charged battery.

Electrical System Basics

Electricity, simply put, is the flow of electric current in the form of free electrons moving along a conductor. The free electrons transfer from one atom to the next but do not physically travel. The more free electrons a material has, as in the case of larger diameter wire, the better it conducts.

Direct Current

An electric current flowing in a constant direction, having a magnitude that does not vary or varies only slightly.

Alternating current

A flow of electric charge that undergoes periodic reversal in direction.

Voltage

A unit of pressure that is applied to the electrons to cause them to flow and can be measured as the difference in electric potential between two points in space.

Amperage

The term amperage describes a flow rate of electric current. This electric current value is measured as a specific number of electrons flowing past a point and is expressed as amperage.

Ohm

A material’s opposition or resistance to the flow of electric current is measured in ohms. There are three principal factors that determine the amount of resistance: size of the conductor, material the conductor is made of and the temperature of the material.

Relay

An electromechanical switch operated by a flow of electricity in one circuit that controls the high current flow of electricity in another circuit.

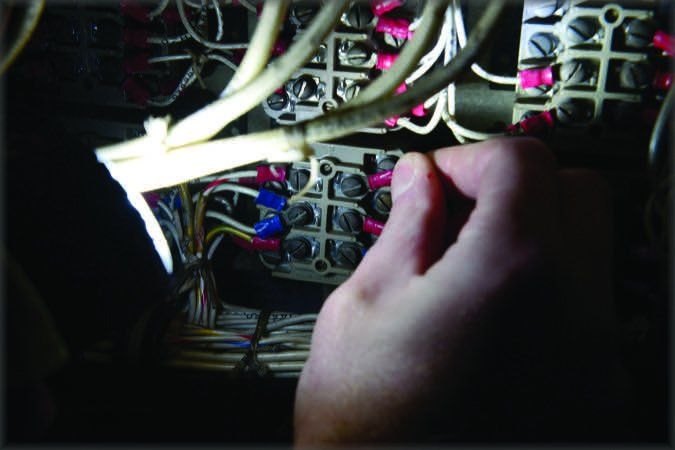

Inspection and Maintenance

According to the FAA Advisory Circular 43.13-1B, Acceptable Methods, Techniques, and Practices-Aircraft Inspection and Repair—the essential resource for anyone working on an aircraft—”The satisfactory performance of an aircraft is dependent upon continued reliability of the electrical system. Damaged wiring or equipment in an aircraft no matter how minor it may appear to be, cannot be tolerated. Reliability of the system is proportional to the amount of maintenance received and the knowledge of those who perform such maintenance.”

While inflight electrical failures and fires are somewhat rare, factors affecting system reliability often reveal themselves on electrical wiring and components. This includes corrosion, broken wires, damaged insulation from heat or fluids (motor oil, hydraulic fluid or fuel) and abrasion. Electro/mechanical devices such as relays, switches and circuit breakers can fail due to frequent or infrequent use, age or improper voltage/current. Repairs to aircraft electrical components such as alternators must be accomplished according to approved procedures.

While aircraft alternators resemble automotive or marine units, the repair parts for an aircraft component must be FAA approved for the exact application. Unapproved slip rings or brushes may fit and work for a short time, but when high loads are applied at altitude, an alternator may fail just when you need it the most.

Owner-Performed Electrical System Maintenance

As an aircraft owner, there are a few electrical system items that can be repaired or replaced as preventive maintenance by a private pilot. Most electrical repairs, however, are required to be accomplished by a licensed mechanic.

Aircraft battery servicing and replacement, repairing landing light circuits, replacing lenses, reflectors and bulbs in position and landing lights are approved as preventive maintenance items. While repair or replacement of these items may seem like a simple task, your aircraft’s maintenance manual may specify a mandatory procedure or instruction. Always deactivate the electrical system prior to maintenance by disconnecting the battery.

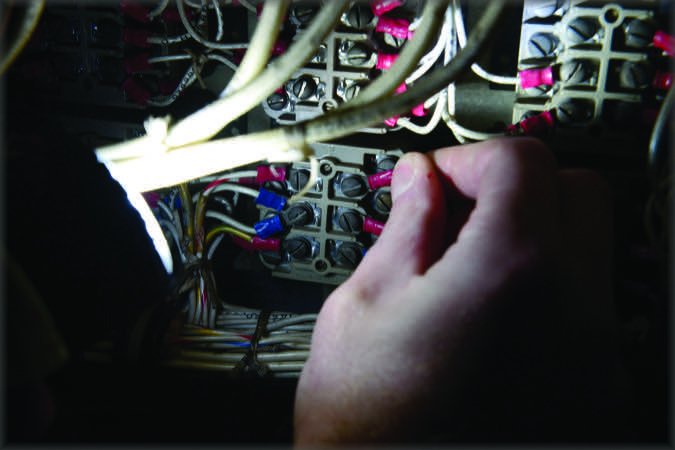

Old wiring like the corroded electrical cable shown at top right can be cleaned up and reassembled with new hardware. Sometimes, it’s smarter to replace wiring like these aluminum cables with new copper.

Insulating boots can’t be effective if they’re not properly installed, as depicted in the middle image at right. To minimize corrosion in and near the battery box, disconnect and remove the battery before servicing.

At bottom, even something simple like replacing a landing light can become complicated if it’s mounted in a cowling like the one shown at bottom. It may not be feasible to replace without removing the cowling—maybe a two-person job—when there’s no external access.

Batteries

Aircraft batteries are an integral part of the electrical system and must be properly maintained and checked on a regular basis. While there have been several advances in storage battery technologies in recent years, the basic lead-acid battery is still prevalent in most general aviation applications, and we’ll confine this discussion to them.

As their description implies, lead-acid batteries contain poisonous, corrosive materials and proper safety precautions such as eye and skin protection must be utilized. During use or charging, these batteries give off a flammable gas which must not be allowed to collect in the aircraft or in an enclosed area. Aircraft are designed with an enclosed battery box containing inlet and outlet air vents to discharge gas and acid overboard. These vents must be kept open, and the battery box must be closed for this safety feature to work. When servicing a battery, there can be a danger of a fire or explosion when a short circuit occurs between the positive and negative terminal of a battery.

Occasionally batteries become discharged and when this happens, it is usually at a time when the pilot is in a hurry and has a schedule to keep or the weather is other than desirable. There have been several unfortunate accidents in past years with improper procedures (hand-propping or jump-starting) used to start an aircraft with a dead battery. The proper procedure to correct a dead battery problem is to remove and replace the battery with a serviceable unit or recharge the battery at a low rate of charge out of the aircraft. Once it’s charged, capacity test it and if it tests a good, then reinstall it.

The two important functions of a storage battery are to start the engine and the ability to utilize the battery as a backup power source in case of a generator or alternator failure. Hand-propping or jump-starting a dead battery and betting the normal charging system will restore it is not smart airmanship. There’s a reason the battery is discharged, one the aircraft’s system likely can’t handle.

An extended, excessive charge from a generator/alternator will further damage an aircraft battery and cause an explosion or a fire. Unlike automotive batteries, an aircraft battery uses much thinner, lighter materials to reduce weight, and they can be damaged by excessive charging. While an open circuit voltage check can be used to a battery’s status, the only way to determine its actual capacity is to perform a capacity or load test. Instructions for continued airworthiness from at least one manufacturer (Concorde) recommends an annual capacity check. Passing such a check is the only way to determine whether the battery will continue to provide expected service.

Dead Battery?

Some aircraft are equipped with an optional ground service plug allowing for the use of an external battery or power source to assist in cold-weather starting or doing maintenance on the aircraft without using the aircraft’s battery. It also can be used to jump-start a dead battery, but it’s usually a really bad idea to take off with a dead battery.

The instructions for using a ground service plug for the specific aircraft should be read and understood before plugging anything into it. Some models do not allow electrical power from the service plug to energize the electronic equipment, protecting them from possible damage. Some do. Ensure that the ground service power source is correct for the aircraft (i.e., 12- or 24-volt system) as incorrect voltage may damage electrical components.

Lessons learned

It’s important to know your aircraft systems, and to read and understand the various reference materials, especially when it comes to abnormal and emergency situations. In the case of a total electrical failure, portable devices such as a GPS or handheld com radio—or maybe a cell phone with the phone numbers of flight service or air traffic control—will come in extremely handy.

Several years ago, while I was based at a small airport in New England, a local pilot in a Cessna 150 found himself in a predicament that could have turned out much worse than it did. While flying on a beautiful fall day, the alternator failed, something the pilot didn’t notice. He flew for some time and eventually glanced at the fuel gauges that both were indicating empty. The aircraft battery was completely dead, nothing electrical was functioning except the independent engine ignition system driven by magnetos.

He got very concerned that he was running out of fuel and elected to land at a nearby airport. The airport he hastily decided to land at was short, and together with the flaps not working, and a little extra airspeed on final due to his excited state, he landed long. The long landing at extra speed with no flaps put the 150 just off the end of the runway into some brush, slightly damaging the aircraft. The pilot and passenger were not injured.

Had this been at night or in IFR conditions or even in a busy air traffic area, the outcome could have been much more serious. Monitor your systems, know where you are and what options are available as you may have to land at the nearest suitable airport. Keep your calm, fly the plane, give some thought to dealing with the problem effectively and execute your plan without indecision.

Mike Berry is a 17,000-hour airline transport pilot, is type rated in the B727 and B757, and holds an A&P ticket with inspection authorization.