As the oft-paraphrased aphorism goes, all is well when the ties that bind us are stronger than the stresses that can separate us. The same goes for parking an aircraft. When we properly secure it after a flight, it’s reasonable to expect it’ll be there when we return. Once we release the ties that bind it, our aircraft will again provide us with reliable transportation. Most of the time, that is how it works. Other times, just a little inattention and improper securing of the aircraft—or improperly reversing the process during the preflight inspection—can and does lead to accidents.

It is hard to learn much about tiedown errors from the NTSB because a tied-down airplane isn’t in motion, so there is usually no report. However, there is ample material in NASA’s Aviation Safety Reporting System (ASRS) database from the self-reported NASA forms people use to admit their mistakes (and avoid potential enforcement actions) in the hope other pilots can learn from them. The bottom line is that properly securing an aircraft outside (i.e., not in an enclosed hangar) is a safety system that doesn’t always get the consideration it deserves. So here are some of the weakest links we’ve found in the tiedown chain.

Preflight

One of the most common ways pilots are bitten by poor tiedown practices isn’t from their failure to properly secure the aircraft, but rather by their failure to completely free the aircraft prior to startup and taxi. Some of the stories are astounding.

Before a predawn flight in a Cessna 182, the PIC’s headlamp-supported preflight inspection was interrupted by the arriving passenger. The PIC picked up the preflight inspection at the tail, the point where he had left off.

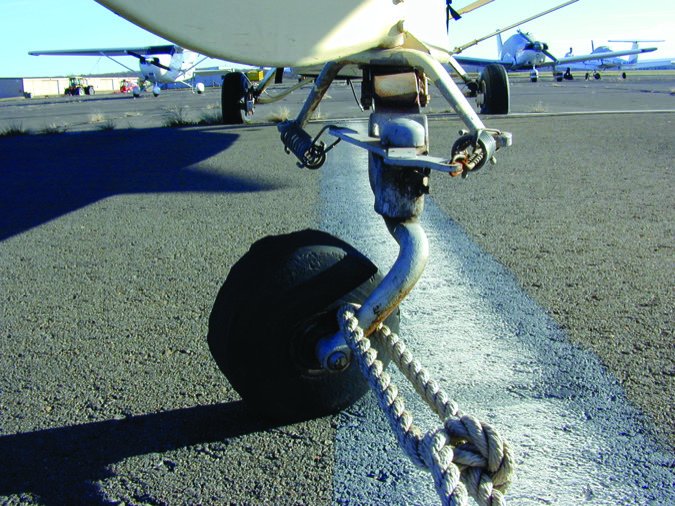

“I did not see the tail tied down to a black tire filled with cement beneath the tail and the anchor rope was dark grey and nearly invisible in the available light. I had looked underneath the elevators but missed the tiedown rope. This was exactly where I had been interrupted.”

Upon taxiing away from the tiedown area, the pilot noted a bit of resistance. So he verified the chocks were out of the way and added a bit more power, enough that the aircraft rolled relatively easily. The pilot proceeded to the runway to prepare for takeoff.

“Upon lifting off there were some rather significant ‘bumps’ that felt like turbulence. The pax remarked that it was ‘bouncier’ than usual. Once airborne, however, the aircraft developed an oscillation that was impossible to trim out.”

The pilot continued flying his low-level survey mission, all the while dealing with oscillations that “seemed too regular to be related to the wind.” When the pilot returned to the airport after completing his mission, he did a straight-in approach. At 65 mph in the landing flare, the Cessna 182 dropped abruptly and experienced a hard landing, but nothing was damaged. Upon exiting the aircraft, the pilot noted a rope hanging from the tail tiedown ring, and a 100-150 lb., cement-filled tire was found on the runway near the point of touchdown. Surprisingly, the aircraft had remained in a flyable CG and the rope held until subjected to the landing force. Stories like this are one more good reason why rear tiedown rings, in particular, need special attention during the preflight.

Unintended items hanging from main or strut tiedown points also deserve attention. Scales used for weighing passenger bags, for example, have been known to hitch a ride from point A to point B. The point is to make sure your tiedown rings do not have ropes, chains or other items still attached.

The Basics

Aircraft tiedown points are structurally reinforced locations on an airframe identified by its engineers as appropriate for securing the aircraft. Typically, they come in threes, one on each wing and one for the tail. If you tie down an aircraft using any feature other than the designated tiedown point, you run the risk of overstressing or damaging it.

Anchor points can be a weak link all by themselves. Tail tiedown rings are particularly subject to abuse by dragging the tail during takeoffs with an overly steep pitch angle and/or hard landings. It is not uncommon to see a round eye-bolt with a flattened side due to an over-rotated takeoff or landing. And if the damage looks fresh, you may have a problem.

Not only do you need to use your tiedowns, you need to inspect them for damage. In one ASRS report, the FAA busted a CFI and student during a ramp check for flying a nonairworthy aircraft. The problem? The tail tiedown was damaged and physically loose. They didn’t catch that in their preflight, but the FAA sure did when they landed.

Taxiing

Just reaching the designated tiedown area can be hazardous, often with major consequences. I read about dozens of events where pilots discovered holes, ditches, cables and other obstructions while proceeding to an unfamiliar tiedown area. In one incident reported in the ASRS, the pilot chose to approach a recently mowed tiedown area from behind, partly to orient the plane into the wind and partly to assure appropriate clearance from other aircraft that made wing clearance too tight for the more traditional taxiway approach. Unfortunately, the recent mowing disguised a large hole that gobbled up his nose wheel, resulting in a prop strike.

Another somewhat common issue happens when pilots make a precautionary landing at an unfamiliar airport to avoid incoming weather. Their problem is timing. There were several reports where pilots landed well ahead of the storm, but didn’t arrive at the tiedowns before the storm’s gust front hit. Lesson: If you are diverting to escape weather, don’t cut it so close that there’s not enough time to properly secure your aircraft after landing.

Persistent and unrelenting winds, especially in regions where there are open plains, may also require conscientious forethought, especially if you fly light high-wing airplanes, a light sport aircraft or taildragger and the winds are near liftoff speed. Many airports with notoriously high winds are staffed with ground crews who understand the pickle some pilots will find themselves in after they land. These are the times when your plane is stopped, sort of, but you can’t really get out to secure it because it might take off on its own as soon as you step out of the plane or are no longer on the brakes. This is when an outside assist comes in handy to help secure your new weathervane against the high winds trying to turn it into a kite.

The next time winds are over 30 knots and you need tiedown help, try calling the FBO by phone or on Unicom to recruit a couple of “strut runners” who know how to arrest a slow-moving aircraft by the struts. Call them marshalers with benefits.

Locks, Covers and Plugs

While our aircraft is sitting, we often cover exposed orifices to protect against foreign debris and damage. There are good reasons to not have birds’ nests in the engine, or insect nest debris in the pitot tube. Pitot covers and cowl plugs are designed to be obvious, often obnoxiously bright with streamers, but they are still forgotten. There are a lot of incidents of ingested cowl plugs and aborted takeoffs when the pilot realizes the pitot cover is still in place.

Gust locks can be even more dangerous to forget about. Most small planes use yoke-based mechanical gusts locks or, in some cases, a seat belt secures the controls. Both are hard to miss, which is helpful because they often can’t be easily removed when under a load. But more sophisticated aircraft can have mechanical gust locks that will produce fatal angles of attack if they are not removed when the aircraft is brought to full power at takeoff. If your aircraft has a gust lock feature that by anyone’s measure isn’t obvious, it should probably be on the preflight checklist (or your own mental checklist)…maybe twice.

Cargo

Cargo is one of the more consequential and often overlooked tiedown considerations. During takeoff acceleration and climb, large, poorly secured loads can shift to untenable CGs, usually resulting in a fatal stall/spin shortly after takeoff. If your load has this potential, you’d better have good tiedown straps and know how to find and use the appropriate structural locations on the airframe to secure your load.

Encounters with turbulence or the forces of deceleration during a forced landing are both excellent reasons to secure cargo and other objects with tiedowns. The last thing you need are projectiles flying through your cabin with the force of four to 10 times their 1G weight.

I was in the audience at a recent safety stand down where John and Martha King told a harrowing story of a forced landing due to icing (and other factors) early in their careers. After violently bringing their 210 to rest in a snow-covered cornfield, they found themselves pinned in by the unsecured luggage pressing against their seats. They eventually got out, but Martha had head injuries from an unsecured toolbox that was sent through the front windscreen by the force of the landing.

One lesson I learned from Stan DeLong, which I didn’t pass along in “Lessons From A Veteran Cargo Dog” (February 2018), is his meticulous attention to securing cargo. After 50 years of flying, something tells me his habit of securing cargo is the result of experience.

Post flight

There are good, usually obvious, reasons to secure our aircraft after we land. The trick is to not get lazy or make overly optimistic assumptions about how brief your pit stop might be. Delays occur. Storms and other events can pop up suddenly. Sometimes delays can last hours, even days. Your best bet is to secure your aircraft like a storm is coming. It might even be true.

When you tie down, don’t forget your gust locks. They can be secured at the yoke, or perhaps they are built into the aircraft. In some cases, there are other mechanical systems to secure the aircraft as well, inserted somewhere on the airframe to prevent undue oscillation, play and damage while the aircraft is tied down.

I recently taxied past a row of planes at the Burns, Ore., airport on a day when the wind was 30 gusting 45. As I passed, I could see two planes whose horizontal stabilizers were violently oscillating at their full range of motion several cycles a second. I can only imagine the wear and potential damage that was occurring internally to jackscrews, bulkheads and stops. Had the planes been properly secured with a gust lock, those horizontal surfaces would have been motionless.

Do A Second Walk-around

It is easy to become a victim of tiedown mayhem, especially if you are spoiled by having a hangar and rarely have to park outside. It is a good idea to always do a second walk-around after your main preflight or post-flight activities to look for things that might not be on your checklist. Verify and reverify everything that should be added or removed to keep everything and everyone safe, like chocks, tiedowns, pitot covers and gust locks. In every case, they should either be completely and correctly in place…or absolutely, positively removed.

The EAA Way

Each year at the Experimental Aircraft Association’s weeklong AirVenture Fly-in, thousands of transient airplanes are parked in rows wingtip-to-wingtip on the open grass areas adjacent to the main runways. Although each airplane is required to be tied down, Wisconsin’s often-unpredictable weather can turn the event into an insurance underwriter’s nightmare.

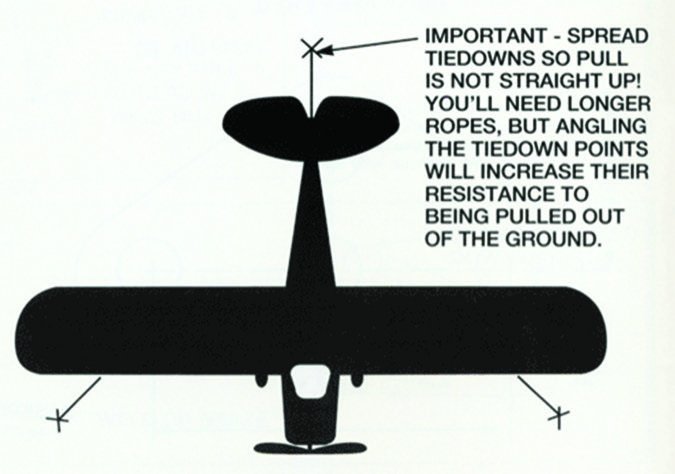

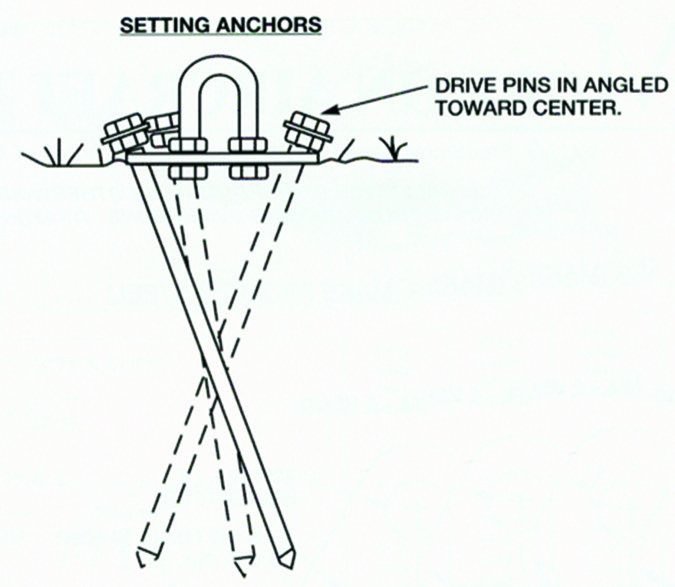

Perhaps with that in mind, the EAA has developed a series of recommendations on tying down airplanes at the show, one of which is pictured at top right. They’re available online at tinyurl.com/avsafe-tiedown. The two images at lower right illustrate the EAA’s preferred methods for anchoring and securing ropes. Some highlights from the EAA’s recommendations include:

“EAA does not recommend the ‘doggie ring’ style that can quickly fail. The triangle-shaped top portion straightens under heavy loads and the anchor can easily be pulled from the ground. Screw-type tiedowns are also not recommended. Both the auger and spiral style loosen the surrounding dirt as they go into the ground, weakening their anchorage.”

“Effective tie-down anchors can also be made from -inch diameter steel rods with a minimum length of 18 inches. The stakes should angled away from the airplane and be driven all the way into the ground at an angle of at least 30 degrees. All anchors should be placed outward from the aircraft, not directly underneath the wing.”

“Effective tiedowns also depend on the quality of the rope. The best ropes are UV-resistant braided nylon or dacron. Manila ropes are not recommended because they shrink when wet, are subject to mildew and rot, and have considerably less strength. All ropes should be regularly checked for damage due to chafing.”

“Planes should be tied down only at the tie-down rings. Tying rope to a strut can cause damage and may bend the strut. The tension of the tie-down ropes should allow for 1 inch of movement. Too much slack allows the aircraft to jerk against the ropes and can cause structural damage. The jerking motion can also pull out or damage the tiedowns. Tight tiedowns impose inverted flight stresses that many aircraft are not designed to withstand.”

Manufacturer recommendations

When in doubt about how to secure an airplane, you can’t go too wrong by following the manufacturer’s recommendations found in the POH/AFM. The good news is all manufacturer documentation basically reads the same. Here’s how Cessna recommends securing its Model 172S Skyhawk SP:

Parking

When parking the airplane, head into the wind and set the parking brake. Do not set the parking brake during cold weather, when accumulated moisture may freeze the brakes, or when the brakes are overheated. Install the control wheel lock and chock the wheels. In severe weather and high wind conditions, tie the airplane down as outlined in the following paragraph.

Tie-down

Proper tie-down procedure is the best precaution against damage to the parked airplane by gusty or strong winds. To tie-down the airplane securely, proceed as follows:

1. Set the parking brake and install the control wheel lock.

2. Install a surface control lock over the fin and rudder.

3. Tie sufficiently strong ropes or chains (700 pounds tensile strength) to the wing, tail and nose tie-down fittings and secure each rope or chain to a ramp tie-down.

4.Install a pitot tube cover.

Mike Hart flies his Piper J3 Cub and Cessna 180 when he’s not schlepping people and packages for a Part 135 operator. He’s also the Idaho State Liaison for the Recreational Aviation Foundation.