A few years ago, an engineer, friend and pilot shared a story about retrieving his Cessna 182RG from the paint shop. Before he took the plane out for a run-up and test flight, he asked his even more meticulous engineer-spouse do the preflight. When she did, she discovered something rather important. The bolts and nuts that connected the elevators were just hand-tightened, unsecured by cotter pins. The bolts and nuts securing the primary pitch control surfaces were essentially ready to fall out. Not good. My friend managed a major nuclear facility in Idaho, and he shared the story with his workforce as an example why operators should “trust, but verify” others’ work.

He cited a statistic indicating a 10-to-30-percent error rate is endemic with just being human and performing tasks. Even though 90 percent seems good by comparison, it’s not when considering whether or not the elevator control surface is firmly attached. As numerous articles and commentary in this magazine attest, any time you retrieve a plane from a mechanic, you become a test pilot. You want to ask questions to learn exactly what systems were worked on so you can pay particular attention to those systems during preflight. The thing is, when a plane comes out of a paint shop, nearly every system on the aircraft has been worked on.

Not a Beauty Salon

A paint shop is a lot less a beauty salon for your aircraft than a concentrated airframe and powerplant shop with a focus on making the skin pretty. When your plane goes into the paint shop, nearly everything on the plane is removed, stripped and/or masked off. Once it’s clean and prepped, it’s then sprayed with a sticky liquid—the paint—which dries into a hardened solid. Then all the pieces and parts are put back together.

Once the aircraft is reassembled, tape is often left in places it shouldn’t be, and paint can be over-sprayed and dry on critical components, like landing gear squat switches. Given the complexity of the process and all its moving parts, the act of picking up a plane from the paint shop requires a particularly high level of preflight diligence. Based on my own recent experience picking up a plane from the paint shop, I suspected a perusal of NTSB reports and the NASA ASRS database would confirm there are some basic lessons we can take away. I wasn’t disappointed.

After a plane, maybe your plane, comes out of the paint shop, your attention to detail will be critically important. To help organize your inspection, here are some of the things you should pay particular attention to.

Missing Fasteners

When a paint shop removes things like spinners, flap seals and strut cuffs, that requires removing the screws. After painting, parts often are reattached with new hardware and should be reattached with all their screws. That’s because if they aren’t completely screwed, you might be.

When I picked up one of my employer’s Piper Navajo Chieftains from the paint shop, I paid particular attention to the screws that held on the spinner because they bear perhaps the highest stress of any fastener on the airframe. Sure enough, one was loose, and anything loose will eventually go missing. I called the mechanic over to tighten it.

A little research in NASA Aviation Reporting System (ASRS) and NTSB reports showed I am not the only one to find loose or missing fasteners and other components after the paint shop. A Beech Baron was on a first flight after leaving the paint shop and was descending from 7000 to 4000 when the pilot heard a loud bang and continuous pounding from the bottom of the plane. The pilot slowed down and declared an emergency. Another aircraft flew alongside and could see that the left wing root seal had come loose and was hitting the bottom of the plane. The pilot was able to safely divert and land for maintenance.

Meanwhile, a Boeing 737-300 crew found many holes simply painted over in lieu of the proper fasteners. Mechanics found a total of 25 missing fasteners.

Control surfaces

In the course of general maintenance, larger aircraft parts like flaps, ailerons, elevators and rudders are rarely removed or disconnected. But they are when the airplane goes into the paint shop. Coming out, you need to give them your full attention; a standard “controls free and correct” check won’t cut it.

When I picked up the Chieftain, I not only “boxed” the controls by pulling them to full deflection while noting the feel when they hit the stops, I also turned the yoke to its full deflection. If they are rigged correctly, the thumb on the top of the yoke will point to the upward deflecting aileron. Thumbs up indicates correct rigging. But it doesn’t always happen that way.

The pilot of a Beech 1900 coming out of paint did a thorough preflight including the standard “controls free and correct” check. The pilot, however, did not see or verify which direction the ailerons deflected. After returning from the first test flight, the pilot reported the ailerons were rigged so that controls were reversed.

Fuel system

We pilots tend to take lots of components in the fuel system for granted. Those tank vents, which occasionally drip when you overfill the plane, are there to allow air to displace into the tank as fuel is consumed. If they are sealed closed, even the force of gravity will not overcome the vacuum pressure, as closed as a straw full of liquid with a thumb over the end. Verifying they are open, with no tape from the paint job still covering the hole, can be rather important.

Fuel cap gaskets are another fuel system component we often take for granted. Tight gaskets prevent the low pressure that is created by airflow over the top of the wing from sucking gas out of the tanks. Fuel cap gaskets also keep water from precipitation out of the tanks.

On one of the first flights after the Chieftain was painted, I topped off my tanks at an out station and glanced out the window on departure to see a vapor trail of fuel escaping the tanks. That sight is memorialized in the image on page 16 and this month’s cover. (After I returned to the airport, I was razzed by the locals for trying to take jobs away from the local crop dusters.) The culprit was the cap gaskets. The caps had been painted, which requires removing the gaskets then putting them back on and adjusting the assembly after painting. Adjusting them again corrected the problem and new gaskets were ordered.

Doors, latches and openey/closey things

While preflighting the Chieftan before its first test flight, I noticed that the oil filler door latch did not close cleanly. The release button for the flap was still covered with a bit of tape to protect the button’s shiny metallic finish, so I removed the tape. But the door still did not close cleanly until I found and removed a bit of overspray from the outside of the door. The door finally snapped shut cleanly, but I kept an eye on it for a few more flights.

On departure from the paint shop, the cockpit door of a Beech Baron came open. The takeoff was aborted and the door was secured. On the second departure, it came open again. The plane returned to the airport and secured the door again. During the flight, however, the plane door slowly worked its way open a third time. The plane diverted. A door latch pin was adjusted by mechanics at the diversion airport.

Take Your Time

I spent a full hour pre-flighting when I picked up the company’s Navajo Chieftain from the paint shop this fall. Then I did a taxi test and shutdown, and rechecked the plane again. It was a clear, warm, sunny day, and easy for me to take my time. When I finally took it airborne, I did a one-hour test flight checking all systems, including deice boots, prop heat, etc.

During my preflight, I found some tape where it shouldn’t be, overspray on a few latches and Zerk fittings and some loose screws. I was prepared to call the paint shop to have their mechanics back to fix whatever I found. Fortunately, they did a great job.

We always do preflights because sometimes we find things. Coming out of paint, there is just more to find.

The images above memorialize my airplane’s trip to the paint shop. In the top two images, removal of control surfaces, tip tanks and plastic/fiberglass components is complete, along with stripping off the old paint, sanding and filling imperfections, and masking surfaces that won’t be refinished. The third image shows some of the components that were removed, including the cowling, flaps, ailerons and elevators. These parts usually are refinished off the airplane because of the need to paint both sides, balance control surfaces and reinstall items like static wicks before reassembly. At bottom, the finished product got a close inspection before flying. If memory serves, two squawks were discovered before the test flight and another during it. — JB

Landing Gear

You will want to pay particular attention to retractable landing gear because the fit and operation of the gear components are particularly subject to painting. Ask the paint shop whether the gear was tested on the jack stands after painting. If they did, at least you know it has been ground-tested. What else should you be looking for? At the risk of being facetious, everything.

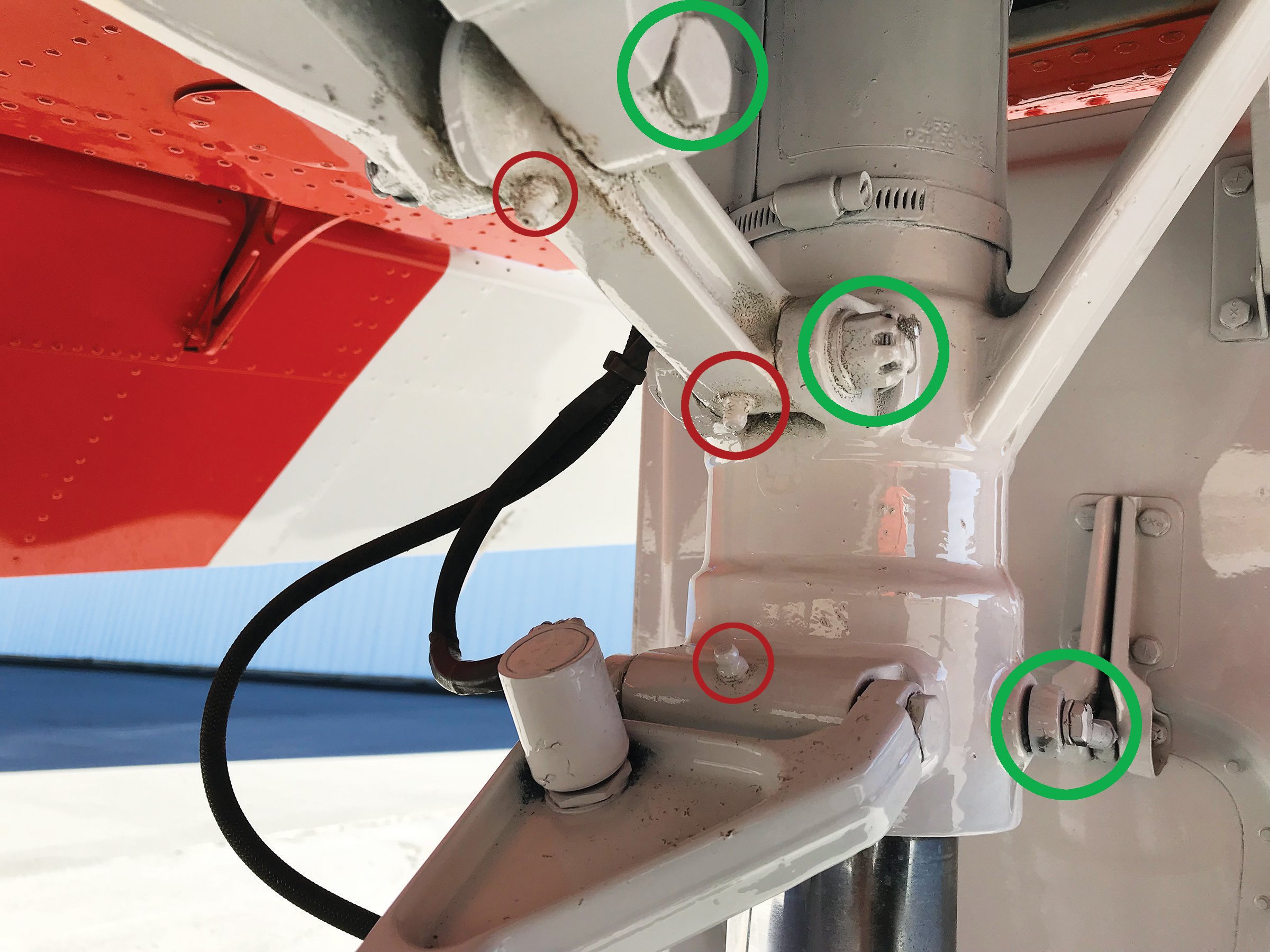

At right is a close-up image of the Chieftain’s main landing gear. Circled in red are Zerk grease fittings, which were painted over. That’s typical, unless your paint shop tapes them over or replaces them, which can get pricey for the extra labor involved. They’re relatively cheap and easy to replace.

Typically, the nuts and bolts holding the landing gear together (circled in green) also will be painted, which can complicate inspection and maintenance in the future.

Static Ports and Antennas

Static ports are an obvious preflight item, especially coming out of paint. The paint shop should have taped it over to prevent it from getting sealed by paint, and that tape should have been removed when you took the plane. It sounds like a simple check. On the other hand, perhaps not. You might even discover your plane has more than one static system.

That’s what happened to the pilot of an L39 Albatross. Although the jet’s two altimeters cross-checked on the ground, once airborne ATC informed the pilot that his Mode C returned a 2000-foot difference between the altimeter he was using and the one reporting pressure altitude to controllers. The flight diverted to a nearby airport.

A corporate jet discovered its FMS and DME equipment generated a 13-mile discrepancy due to a painted antenna causing interference.

More Weighty Matters

Recently, I had the opportunity to pick up another Chieftain from the same shop. I had preflighted the same airframe post-paint, but there were a few other factors to consider. First, I was on a regular early morning flight schedule, getting up at 0530, and on the day the plane was supposed to be ready, I could not get there until after dark. A weather system was coming in and I would need to fly at night.

I declined the flight, not only because the end of a long day is not a smart time to schedule a critical pre-flight inspection, but because there were just too many hazards to ignore. When it is my turn to fly that plane again, I will give it a good once-over, just in case.

Mike Hart is an Idaho-based flight instructor and proud owner of a 1946 Piper J-3 Cub and a Cessna 180. He also is the Idaho liaison to the Recreational Aviation Foundation.

Excellent article. You might add there is an absolute imperative to re-weigh the aircraft after it is painted, and periodically to assure empty weight is accurate. Several years ago a CAP plane I flew was looking ratty so it was re-painted. However, it wasn’t re-weighed because ‘it was just new paint on bare metal’. Later a new maintenance shop weighed and “discovered” the empty weight had grown by 110 pounds. After some sleuthing they found it wasn’t stripped and a long past calculated change in the W&B had overlooked a 10 pound addition of a new gadget. So the second addition to the article is to re-weigh every five years or so.

I am a retired RAAF and Civilian LAME When an aircraft was painted it was always Inspected by a dual Inspector {Someone Independent not involved in the work} or a second Lame independent of the work the aircraft was reweighed flight controls Balanced, refitted usually with new hardware, a set of panel screws were painted and replaced complete set of fasteners was painted and fitted Undercarriages were removed stripped to components painted reassembled fuel caps were fitted with new O Rings and vents inspected Pitot and static vents were checked system ops done we were a Professional outfit job done right the first time

Here’s a link to a Piper PA-31P that crashed on May 21, 2021 after it came out of a paint shop out a paint shop located at Myrtle Beach International Airport (KMYR). The airplane crashed on its first flight out of the paint shop due to trim tabs being reinstalled upside down and reversed.

Here’s a link to the Aviation Safety Network report:

https://aviation-safety.net/wikibase/262221