A friend of mine died recently when his airplane crashed. He was returning to his home airport when the engine failed and his plane crashed short of the destination. Brad “Launchpad” Marzari was what I call a stone aviation junkie, as evidenced by his frequent, enthusiastic presence at major air shows like Sun ‘n Fun and AirVenture, which is how I knew him. He loved flying and the people involved in it, both of which are in abundance at those events. I didn’t know Brad as well as many others—we never flew together, for example—but we occasionally traded emails on one topic or another. He traveled to Germany frequently and always had some German chocolate to share. I still have some.

About this time a year ago, we discussed the annual inspection on his Focke-Wulf FWP-149D, a German-built copy of the Piaggio P.149, a four-seat piston single designed in the 1950s for military liaison and training. Brad’s airplane was manufactured in 1960, according to FAA records, and he acquired it in 2019. Our last email exchange commemorated his first experience with an annual inspection. The airplane was previously registered in Canada, and its U.S. airworthiness certificate was in the Experimental-Exhibition category. The NTSB recently released the preliminary results of its investigation and…it’s sobering in a number of ways.

LINKS IN THE CHAIN

Like so many other accidents, there was a chain of events. The first link involved what at the time was believed to be a magnetic chip detector alerting to metal in the oil. The NTSB’s investigation discovered the warning light had been mislabeled; it instead indicated an open bypass valve in the aftermarket oil filter assembly. No one knew this at the time, but the mechanic noticed the alert during a post-maintenance run-up. The airplane was powered by a Lycoming GO-480-B1A6 six-cylinder, horizontally opposed, carbureted and geared engine. See the sidebar on page 6 for additional details on this engine series.

The mechanic drained the engine oil and inspected the oil filter housing, where he found non-ferrous “metal contamination” on the filter screen and in the housing. Although Brad reportedly wanted to fly the airplane back to its base at Killeen, Texas (KILE), the mechanic apparently talked him out of it, pointing out they needed to determine the source of the metal. Brad left the airplane and the mechanic collected samples of the metal contamination, cleaned the filter housing and added fresh oil before running up the engine again. The erroneus chip detector warning did not reappear.

Brad returned the following day and flew the airplane back to its base at KILE. The mechanic was under the impression the airplane would remain there until lab results from testing the metal were available. That didn’t happen, however. The next day, Brad flew the airplane to an airport 84 nm from KILE. The accident occurred during the return flight.

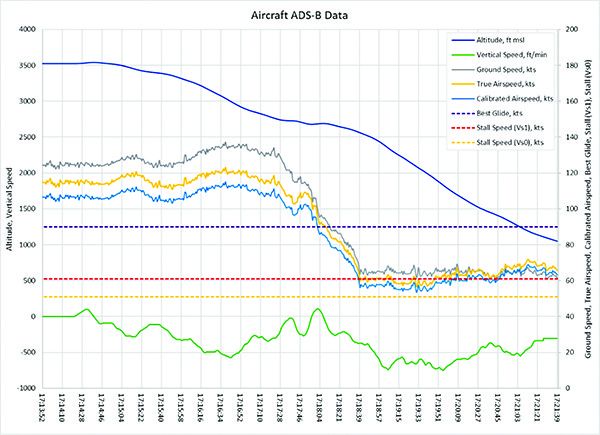

But airspeed continued to decay. Almost immediately, the airplane decelerated to well below its published best glide speed of 90 KIAS and airspeed began to fluctuate near the clean stall speed, VS1. In the last minute or so before the data ends, the airplane accelerated slightly and its descent rate slowed, evidence that slowing the airplane to near its stall speed increased the descent rate.

THE ACCIDENT FLIGHT

While en route back to KILE, at about 1715, when the airplane was level at 3500 feet msl and 13.5 nm from the destination airport, it began descending. After a jog to the left/northwest, it turned right and joined the extended centerline for Runway 1 at KILE. About 20 seconds later, the airplane was established on the extended runway centerline at about 2700 feet, about 1850 feet above the destination’s field elevation of 847.5 feet msl.

Performance calculations performed by the NTSB and based on the flight’s ADS-B data (see the graphic above) show that at about 1717 local time, the airplane began descending as it also decelerated, from about 112 knots to about 60 knots. The airplane’s published clean-configuration, wings-level stall speed (VS1) is 61 knots. According to the NTSB, its “maximum glide distance with no engine power is achieved at 90 knots.” The airplane’s airspeed was between 56 and 69 KCAS, and its descent rate ranged from 300 to 750 fpm during the final three minutes of ADS-B data, which ended at 1721:39. The airplane was 2.7 nm south of Runway 1’s displaced threshold, at 1050 feet msl (about 200 feet agl) and at about 63 KCAS at that time. The airplane came to rest about 2.2 nm south of the threshold.

A witness reported Brad transmitted over the Guard frequency (121.5 MHz) that he had “lost his engine,” was “losing altitude” and “trying to make it to Skylark [KILE].” The pilot then was heard to say he “wasn’t going to make it to the airport” and to “roll the trucks.” A short time later, an ELT beacon was heard on Guard.

Another witness saw the airplane flying toward the airport at about 300 feet agl and “50-60 knots.” The engine was “sputtering.” The witness observed the airplane’s wings dip left and right two or three times before the airplane “stalled” and then descended to the ground in a left-wing-down attitude.

The Lycoming GO-480 engine that powered Brad’s Focke-Wulf is a bit rare and, well, different. Instead of the 2700 rpm at which many aircraft piston engines make their rated power, the GO-480 turns at 3400 rpm for takeoff. Gearing reduces propeller rpm back down to 2700, allowing the engine to make more power and still turn a large-enough propeller at subsonic speeds. The engine is limited to only five minutes of operation at its rated 3400 rpm/270 hp. After that, power should be reduced to no more than 3000 rpm/260 hp, according to Lycoming.

But there’s no free lunch. Geared aircraft engines are heavier and typically feature reduced TBO (time before overhaul) when compared to their direct-drive counterparts. The GO-480 series engines are essentially six-cylinder O-320s with reduction gears on the front; a typical Lycoming O-320 four-cylinder engine will have a TBO of 2000 hours; the GO-480’s TBO is set at 1400 hours (1200 if valves with 7/16-inch stems are installed). The NTSB’s preliminary report on this accident doesn’t detail the engine’s maintenance status but its final report probably will.

In part because of the reduction gears, pilots need to manage engines like the GO-480 differently. For example, Lycoming’s Operator’s Manual for the GO-480 series carries the following warning: “These engines are equipped with a dynamic counterweight system and must be operated accordingly. Avoid high engine speed, low manifold pressure operation. Use a smooth, steady movement of the throttle (avoid rapid opening or closing). If the warning is not heeded, there could be severe damage to the counterweights, roller and bushings.”

As the sidebar on the opposite page details, those apparently are some of the components that contributed metal to the particles found in the engine’s oil by the mechanic and which subsequently failed.

PIECING IT TOGETHER

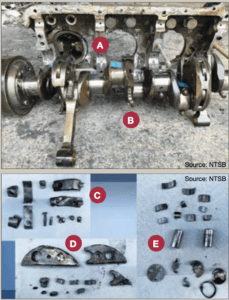

The NTSB has not determined the probable cause of Brad’s accident, and probably won’t for several months. But from the available evidence in its preliminary report, one of the most thorough I’ve seen, it’s fairly obvious what happened. As detailed in the sidebar on the opposite page, the engine failure involved throwing the connecting rods for cylinders #3 and #4, and doing severe damage throughout. The images above, from the NTSB’s prelim, tell most of the tale. What they don’t and can’t tell us, though, is everything that happened in the cockpit.

It’s a tough pill to swallow, but Brad apparently allowed the airplane to get too slow—well below its best glide range speed—and lost control when it stalled. Although we don’t know precisely when/where the engine stopped producing power, it would be illuminating to see a performance analysis based on flying the airplane at its best glide speed, and determining if a successful glide to the runway at KILE was even possible. Additional factors likely will include inadequate maintenance and/or operating the airplane with a known deficiency.

Another thing we don’t know is how the airplane had been flown: Did previous owners/pilots follow Lycoming’s operating recommendations and warnings? Did Brad? Regardless and based on the recovered engine parts and the damage extent, it appears the crankshaft-mounted counterweights at cylinders #3 and #4 failed and quickly took the connecting rods with them, wreaking havoc throughout the engine. Is this the result of failing to heed Lycoming’s recommendations or some other factor? Metallurgy on the previously found metal particles will at least partially help answer this and other questions.

At right, we’ve reproduced two images of engine components from the NTSB’s preliminary report. At top, the right case half and the crankshaft are pictured in as-recovered condition. The bright metal on the crankcase (A) is evidence of catastrophic damage. The counterweights are missing from the #3 and #4 con-rod journals (B), as are the associated connecting rods.

In the bottom image, the connecting rod caps, attaching hardware and what appears to be bearing material are mangled almost beyond recognition (C). The crankshaft counterweights (D) also appear mangled, with one of them fractured into at least two pieces. Piston pins (E) and what appears to be small-end pieces of the connecting rods also show damage and fracturing, along with other miscellaneous components.

Not included here for space limitations is an image of the engine’s oil pan, which shows a sizable hole in what appears to be its right rear. Metal shavings are distributed throughout the oil pan, more evidence of catastrophic failure.

We would wager that most of this damage happened within a few seconds, but it didn’t occur without warning: the metal particles the mechanic found when troubleshooting what turned out to be the oil filter assembly’s bypass alert were a clear sign something was amiss. Once the component failed and started bouncing around the engine, this outcome was inevitable.

POTENTIAL LESSONS

While conclusive answers will have to wait for the NTSB’s final report, we can draw a couple of conclusions. First, engine oil analysis is a valuable inspection and maintenance tool, providing early warning of potential mechanical issues, but only if we pay attention to the results. By contrast, Brad knowingly flew an airplane making enough metal to illuminate the erroneous chip detector warning.

Second, flying the airplane must take precedence over all else when an engine fails. Brad had the presence of mind to advise others of his problem, but let the airplane get too slow, perhaps while trying to stretch the glide. Sitting here in my office, it’s easy to say this, but it would have been far better for Brad to have used his time and altitude to find a suitable field for landing than trying to make the airport and losing control in the process.

Jeb Burnside is this magazine’s editor-in-chief. He’s an airline transport pilot who owns a Beechcraft Debonair, plus the expensive half of an Aeronca L-16B/7CCM Champ.