It’s an article of faith in aviation and other endeavors that having more experience with a specific machine is less risky than having less. In aviation, we measure this by the number of hours accrued in a specific aircraft type. A corollary is that pilots with relatively few hours in-type are at greater risk of making a mistake.

Usually, mistakes are not lethal, and we can easily recover from them. But understanding a problem confronting a low-time pilot and how to fix it can be elusive. It’s not that the low-time pilot doesn’t know how to fly; rather, it’s a lack of familiarity with specific systems and the consequences of doing X when we should have done Y.

One result places the pilot who starts flying a new-to-them aircraft at greater risk of an error, and less well-equipped to understand the error and remedy it before its potential consequences can be realized. Insurers know this, and that’s why they may require a minimum amount of experience and/or higher premiums until it’s gained. The smart pilot with little in-type experience will consider their status and take extra care to ensure they’re doing it right. Transference can be a problem, however, when habits learned on one type prove incompatible with the new type, and need to be relearned.

In this month’s accident, it’s unclear if any of that happened, though. The accident pilot’s experience was estimated to be 180 hours, which ain’t nothing, but it’s not clear in which aircraft they were flown. Regardless, there are some universal circumstances in any airplane that require the same pilot reactions.

BACKGROUND

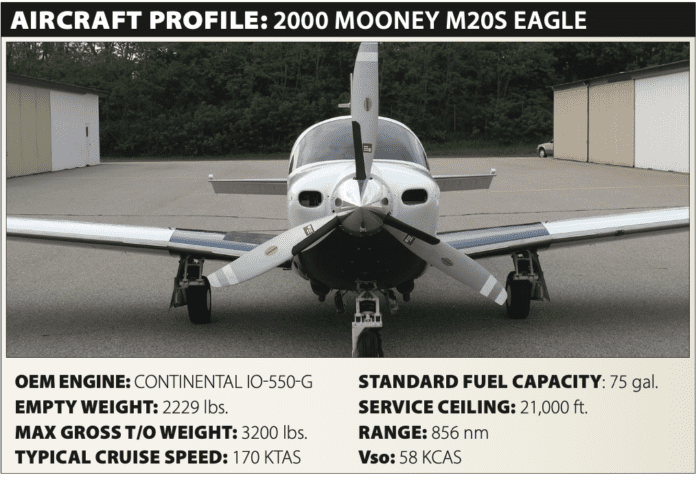

On December 31, 2019, at about 1606 Central time, a Mooney M20S Eagle was destroyed when it stalled and crashed during an attempted takeoff from Olathe, Kansas. The instrument-rated private pilot (male, 48) and the passenger were fatally injured. Visual conditions prevailed.

A witness observed “nothing out of the ordinary” regarding the pilot’s behavior and “no red flags” with respect to his actions. The witness watched them take off for a return flight to their home base; he did not notice anything out of the ordinary. He indicated that, during the engine power-up, “all” sounded and looked normal.

However, he noticed that the airplane lifted off at a much slower speed than would be expected and immediately started to climb at a very high pitch attitude. The witness reported that as the airplane gained altitude, it appeared to fly slower to the point that its left wing stalled, “causing the [air]plane to nose over and continue its trajectory straight into the ground just east of the runway.” The witness stated engine power was “on” throughout the entire flight with no odd sounds noted.

Videos taken near the accident site were consistent with the witness statement. The airplane did not exhibit any in-flight fire or smoke in the videos, and a ground fire was observed after impact.

According to the NTSB, the FAA on March 20, 2012, issued Airworthiness Directive (AD) 2012-05-09, requiring a one-time inspection of the trim fitting, hinge and filler plate of the tail pitch trim assembly for correct positioning and proper attachment. Affected models included the accident airplane, which had been manufactured 12 years earlier. The AD also called for inspecting the Huck Bolt fasteners for proper security on all Mooney models, including the accident airplane. The AD references mandatory Mooney service bulletins applicable to several models, also including the accident airplane. Its maintenance logbooks were not located, also according to the NTSB.

It’s likely the AD was performed. It had been issued seven years earlier, and been an open item on at least six annual inspections. The airplane was recently acquired, and likely went through a pre-buy inspection, which would have identified whether the AD had been complied with. If it wasn’t, compliance likely would have been a condition of sale.

INVESTIGATION

The airplane came to rest about 2550 feet from the departure runway’s threshold. Much of the fuselage was fire-damaged. The propeller was embedded in terrain; examination revealed S-shaped bending and leading-edge nicks, indicating it was under power on colliding with terrain. The right main landing gear was found partially extended; the left main gear’s position could not be determined.

The magneto switch was set to the both position. The mixture, propeller and throttle control knobs were in their forward positions. Data extracted from an engine monitor was consistent with observed operations. There were no pre-impact anomalies precluding normal operation detected during the engine and airframe examination. The airplane did not receive any fuel at Olathe.

The pilot and a co-owner purchased the airplane on November 26, 2019. According to a flight instructor, the accident pilot’s transition training included basic maneuvers, takeoffs, landings, airport entry activities, cross-country activities and go-arounds. He characterized the pilot as a “quick learn” and an “excellent student.” The instruction totaled 6.8 hours of flight time.

Service bulletins and an FAA airworthiness directive issued in 2012 directed one-time inspections of the pitch trim system for correct positioning, security and proper attachment. A mechanic who had worked on the accident airplane told the NTSB, in part, he was “sure” the AD and related service bulletins had been complied with previously or they would have been listed on associated paperwork as an action item.

A fixed-base operator servicing Mooney airplanes supplied photographs of an exemplar trim system jack screw at takeoff and full-up trim settings; when the trim indicator was in the full-up position, the jack screw was fully extended. A post-accident photograph of the accident airplane’s trim jack screw was consistent with the full-up trim setting in the exemplar photographs.

PROBABLE CAUSE

The NTSB determined the probable cause(s) of this accident to include: “The pilot’s failure to set the elevator trim properly for takeoff, which resulted in an exceedance of the airplane’s critical angle of attack during climb out, an aerodynamic stall, and the subsequent impact with terrain.”

Most of us have forgotten once or twice to set the trim before takeoff. Usually, it’s not full down or full up, but somewhere in between. Also usually, we sense the abnormal trim setting at or near liftoff, when the airplane’s nose either pitches up readily or reluctantly. The smart thing to do is abort the takeoff and taxi back for another attempt only after re-running the before-takeoff checklist.

Even presuming the pilot didn’t recognize the abnormal trim setting, it should have been something a lot of forward pressure on the yoke could manage, at least for the few seconds it would take to either adjust the trim and continue, or reduce power and land on the remaining runway. That’s a decision and technique that’s not type-specific—it pretty much applies to any conventional airplane (which the Mooney series is, despite its tail being on backward).

One possibility is the pitch-trim jackscrew was jammed before takeoff in a fashion investigators missed. Maybe the electric trim ran away, or the autopilot malfunctioned. Maybe the AD hadn’t been complied with. Is it also possible the pilot had never been trained on abnormal pitch-trim settings?

Thanks for the interesting article.

Just a short testimony that relates to some points in this story: when I was a very inexperienced 50-hour (new PPL) pilot I took off with the pitch trim accidently set very nose high. It was an electronic trim with a faulty position indicator that didn’t give any true indication of its setting. I had all my 50 hours experience on that aircraft. I did not notice the trim setting until after rotation. Following rotation I was focused on maintaining correct initial climb attitude and speed, but only a few seconds after rotation I found myself fighting with the stick. With significant forward force (using one arm) the aeroplane held the correct attitude and I made the climb out while correcting the trim. The rest of the flight was uneventful and I never again made this mistake.

So, just one antecdote to indicate that a very inexperienced pilot can resolve severely incorrect pitch trim immediately after rotation. Interesting to know that’s with all experience on that same type, so there was a quick detection of a problem.