Almost any assessment of the Accident Briefs section of this magazine’s issues reveals that engine failures, followed by the inevitable arrival back to Mother Earth, pose a significant contribution to the accident record and the NTSB’s workload. What happens after the engine fails isn’t the topic of this article, but what causes the failure—and preventing it from happening—is. At the outset, it’s important to note that engine failures per se are not part of the accident statistics—an engine failure only appears on the NTSB’s (or the FAA’s) radar if the airplane is damaged or its occupants injured. A small airplane’s engine failure followed by a landing in which nothing was damaged and no one was hurt isn’t counted.

Some years ago, I was fortunate to participate in efforts of the General Aviation Joint Steering Committee (GAJSC) to closely examine the underlying causes of general aviation accidents and recommend ways to mitigate them. You may recall some out- comes from those efforts, which include industry-wide emphasis on preventing in-flight loss of control (LOC-I) and the FAA’s relaxed certification standards for angle-of-attack instrumentation installed in small airplanes. Our workgroup focused on powerplant failures. It was a total-immersion opportunity to learn how piston aircraft engines fail, and can be failed. Here are three of the typical engine-failure causes we explored.

1. Mechanical

When we think about engine failures, pilots generally presume they’re due to a mechanical issue, and mechanical issues are something for which a mechanic is responsible. Therefore, the thinking often goes, there’s nothing the pilot can do but accept his or her judgment that it will start, run and develop full power when you ask for it. Nope.

In fact, the pilot is the front-line observer of the engine’s health. You’re the one who checks the oil, wiggles the exhaust pipes, looks for oil puddles on the ground and peers into the cowling. You’re also the one who monitors the engine instruments, leans the mixture, advances the propeller control before adding full throttle and opens the cowl flaps on a go-around. You monitor cylinder temperatures to ensure they don’t get too hot and oil temperature to make sure the engine is warm enough to take off in the winter, after preheating it, of course.

If you’re the owner/operator of an engine attached to an aircraft, you’re the one primarily responsible for its airworthiness, not the mechanic. The FAA says so. You’re responsible for ensuring all the required inspections are accomplished, that any airworthiness directives are complied with and that any work performed is appropriately documented. If you hold a private certificate or better, the FAA also allows you to perform some limited preventive maintenance on it, like changing the oil or cleaning/rotating the spark plugs. And therein lay many more opportunities for mechanical failure, especially if you don’t have and/or use what the agency calls “data acceptable to the Administrator.”

When it comes to engines, this refers to such basic things as manufacturer-approved engine oil and filters, spark plugs, etc. It also can refer to maintenance, disassembly and overhaul procedures, as well as seemingly mundane things like torque settings for plugs and filters, or fuel injectors. Changing, cleaning and reinstalling all of these items, and more, is allowed under FAR 43, Appendix A and its description of preventive maintenance allowed to be performed by someone holding at least a private pilot certificate. It helps immensely to have a mechanic show you how to do these things, just as using the proper tools is mandatory.

Final word about an engine’s mechanical condition: The modern engine monitor is worth its weight in gold when it comes to diagnosing engine issues. The data they record can be downloaded into a spreadsheet and massaged, graphed and otherwise used to identify problems, both short- and long-term. If your airplane doesn’t have one, you’re missing out on one of the best tools available to help you keep your engine running in top shape.

Over the years, I’ve had some memorable engine issues, details of which relate to this article’s main text. Here are three of them.

Cessna 172M: Tri-Cities, Tennessee. After a few hours at altitude, I was cleared to descend and pulled back on the throttle to minimize overspeeding the engine as airspeed built, and then activated carb heat. Almost immediately, the engine coughed, then resumed its normal humming. I had a bunch of time in this airplane and knew what was normal for it. This wasn’t it. I told ATC I might have an engine problem and would not accept a delay. The controller was great, pointing out major highways in case I needed them and cleared me to land, number one, maybe 10 miles out. He also rolled the equipment.

On the ground, I asked a local mechanic to check it out, including a full-power run-up. Nothing was found. I’m convinced it was carburetor ice…the heat I applied melted it into water, which dutifully went through the engine.

Beech Debonair: Wichita, Kansas. I had picked up a colleague in Columbus, Ohio, and launched from there to Wichita, Kansas, with full tanks. We spent most of the flight talking about the people we knew and the projects we’d worked on. As we let down for Wichita, which was landing to the south, that continued. Vectored to about a five-mile final for 19L in good VFR, I had just rolled out of the left turn to align with the runway when the engine wound down.

My verbal reaction isn’t repeatable in a family publication, but I went through the engine-out drill, including switching tanks. The engine immediately restarted and we made a safe landing. Over the three-plus-hour flight, I hadn’t switched tanks. Dumb. The left turn was enough to unport the tank we’d flown west on.

Beech Debonair: Jacksonville, Florida. I had just leveled off at 9000 feet msl after an en route climb from 8000. Over the nose, I could see what is the former Cecil Naval Air Station, with its 12,000-foot-long main runway. All of a sudden, the engine soiled the bed, running very rough. No combination of mixture, prop or throttle movement could fix it. The engine monitor’s CHT and EGT bars were dancing.

I declared the emergency with ATC and asked for the nearest runway, which happened to be Cecil. We were descending anyway, so I set up a low-power glide at the airplane’s engine-out speed. At the key position, I needed two 360-degree turns to lose altitude before sliding the mains onto Runway 27. We taxied in under our own power, with the equipment following. A well-fed Border Collie could have landed the airplane under those circumstances. At night, and/or over water or mountains, maybe not so much. The #5 cylinder had swallowed its intake valve; the day’s flying was done.

2. Fuel-Related

Fuel-related engine failures generally fall into two categories: Fuel exhaustion, when there’s nothing in the tanks left to burn, and fuel mismanagement, when there’s still fuel aboard but it can’t get to the engine, probably because the pilot did something wrong. Of course, the main thing the pilot often does wrong is forget to add fuel before takeoff.

Personally, I just don’t understand fuel exhaustion. My airplanes are based at a field lacking a fueling facility, and if I’m uneasy about how much fuel is in one, I go get more, filling the four five-gallon cans I have dedicated to avgas only. Having once or twice arrived at an en route fuel stop to find there was no fuel available, I always land with enough gas to go get more gas.

Starvation is another issue, though, and I can see where a mechanical problem out of your control—like a failed transfer pump—can mean you have a problem. Electric pumps can be preflighted on the ground, simply by turning on the master, and then the pump switch, and listening.

Perhaps the best solution to suffering a failed pump is to check as soon as possible after takeoff that all pumps you’ll need for the flight work. I can assure you that having a failed pump in a tip tank guarantees a higher in-flight workload as the imbalance takes its toll. Been there, done that. Fuel selectors also can be tested, but—please—do it at altitude. If the selector isn’t allowing verified fuel in a tank to get to the engine, land and figure it out before something goes tilt.

Finally, there seems to be a bad habit on some checklists: switching tanks on the ground, before takeoff. Bad idea. Instead, alter your checklist to start the engine on the tank you intend to use for your takeoff and climb to cruising altitude. Leave it alone until there’s some air under you. I realize that might go against the manufacturer’s recommendation, but I don’t care and you shouldn’t either.

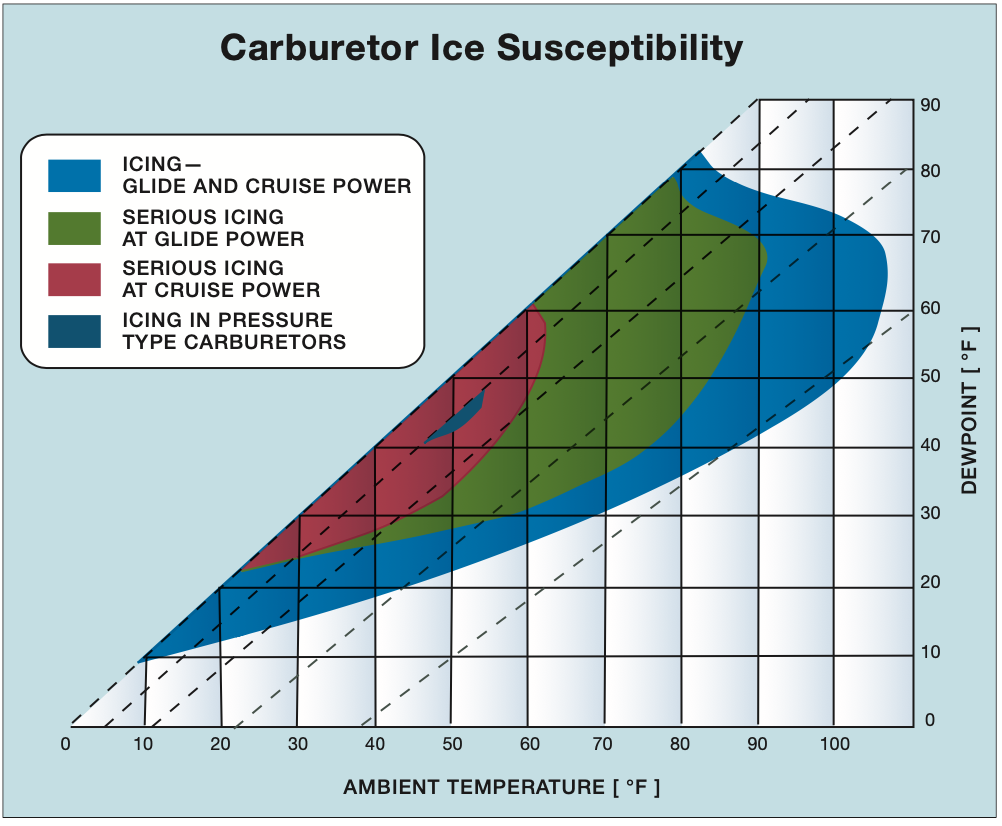

3. Carburetor Ice

If you’re a longtime subscriber, you’ve likely read about an engine failure or three where the engine started and ran fine on the airplane, up to full throttle, without anything done to it after the failure. Having read more than a few accident reports over the years, these events typically have one thing in common: They involved carbureted engines. Yes, the lack of any apparent reason for the engine to fail also occurs with fuel-injected engines, but for different (obviously) reasons, another topic. Of course, by the time someone gets to examine the engine or tries to start it, the offending ice has melted, leaving behind no evidence.

If you fly a carbureted engine, use heat early and often. Apply it periodically to ensure it’s working. Apply it before reducing power. Get a carb ice detector/gauge.

What To Do About It All

An ounce of prevention is worth a pound of cure. The best defense against engine failure is a well-maintained airplane. If it does fail, the best defense against a poor outcome is altitude, which affords you time to troubleshoot the failure and fix it, and/or glide distance to reach a suitable runway. Don’t switch tanks right before takeoff, when you’ll have neither time nor glide distance if something happens. Don’t be stingy with the carb heat. Land early to refuel, and stretch your legs, update your weather information, etc.

Read the manufacturer’s documentation, and consult type clubs and others whose opinion you respect about how to operate the engine, what various abnormalities mean and what you can do about them. Find a good maintenance shop you can trust, preferably one familiar with your aircraft, and listen to them. Ignoring a mechanic’s advice about maintaining your engine is one way to get real-world engine-out practice. Θ

Jeb Burnside is this magazine’s editor-in-chief. He’s an airline transport pilot who owns a Beechcraft Debonair, plus the expensive half of an Aeronca 7CCM Champ.

Excellent article.

I can relate to an experience I faced twice with an engine failure on a single-engine aircraft. Not fun and a bit scary, twice with the same aircraft, in two different scenarios and conditions.

Thank you for your article.

Cheers

Luiz