The Sphinx was a mythological monster who forced passing travelers to answer her riddle, eating those who struggled to find an answer. “Which is the creature that has one voice, but has four feet in the morning, two feet in the afternoon and three feet at night?” Oedipus’s correct answer was that the creature is a human, who starts by crawling on all fours, transitions to walking on two feet, but finally needs a cane, adding a third footprint.

A pilot’s career can be like that, too. A student crawls, staying close to the ground on short trips. Later we move higher and faster, and with a little luck fly a well-equipped turboprop or jet in the flight levels. Eventually, though, age or illness or economics or who knows what forces us to come back closer to the ground, perhaps to scale back our flying ambitions and downsize. It’s easy to think that our vast experience will make one more airplane easy to master, especially if it’s a “small” one. But things don’t work that way, so let’s talk about why. And let’s also talk about how to get ready to answer any riddle.

LIGHT SPORT

The FAA’s regulations have recognized light sport aircraft (LSA)for quite a few years. They’re an interesting compromise. Pilots do not need a medical certificate to fly them; a driver’s license suffices. There is also a special category of flight instructor certificate, CFI-S, for those instructing exclusively in an LSA. The certification rules are supposed to be easier for manufacturers to meet. The compromise is that these aircraft have limitations on maximum gross weight, speeds, altitudes and seats.

Like glider and balloon pilots, LSA pilots assess themselves to decide if they are medically fit to fly. After more than a decade of experience with the regulatory framework, there’s no evidence LSAs are falling out of the sky because their pilots are unfit. Instead, accidents follow the same trends: loss of control, low-level maneuvering, running out of fuel, VFR into IMC, etc.

Of course, LSAs and their pilots are not immune to risk. The fact that there are accidents, especially loss-of-control accidents, emphasizes the need to learn to fly these airplanes correctly, even for those who are very experienced.

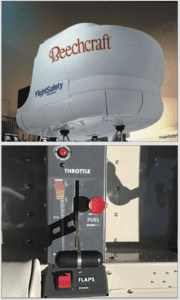

If good training is what you want, very little beats a full-motion simulator for effectiveness, especially for crews of high-performance airplanes. The accident record is full of botched go-arounds, mishandled engine failures in multiengine airplanes and the like, demonstrating there are things best practiced on the ground, in a simulator, instead of airborne. Those and other maneuvers are difficult and often leave little margin for error. But if you crash the simulator, you can just hit reset and try again.

Training does not always go smoothly, either. One of my multiengine students practicing an actual engine failure feathered the correct engine but then impulsively reached over and shut down the magnetos on the good engine. No metal was bent, but I wish we’d been in a simulator that day. I also wish we’d been in a simulator the day my instructor decided to fail one engine, using the mixture control, as soon as I put the landing gear up in a cabin-class twin. And I also wish that we’d been in a simulator when…well, I think you get the idea.

Not that simulators are perfect. Some major training centers don’t change the syllabus often enough, so you know what maneuver is coming next. That is, unless you make a mistake, like trying to take off with the flaps set incorrectly. Then the instructors pile on the nasty surprises.

Aircraft-specific simulator training is much more common in the world of turbine-powered aircraft. For most piston-powered models, training gets done in the airplane. Once one has experienced sim training at this depth, it is difficult to go back to the hit-or-miss examples I have seen (and, deep in the past, probably given). If you want training with more depth—and you should—you have to find it for yourself. So it is when transitioning from a fire-breathing twin turbine-powered airplane to an LSA.

IN THE PAST

For many years, I owned and flew a 1946 Taylorcraft BC-12D, which qualifies as an LSA. So I’m not new to flying very small airplanes. (I’ve also owned a single-seat glider, but that’s a different story.)

The truth is that 1946 is a long time ago, and my Taylorcraft has very little in common with today’s LSA fleet. I used to call it “air-plain.” One of my friends, who had shiny-jet syndrome, asked me about the systems. He’s a smart guy, and that’s the right question to ask about a type that’s new to you. The answer was little more than, “The fuel goes up there and the engine is down there, so gravity is the pump. Let’s go see how you handle stalls with no stall warning.”

THE CHECKOUT

One of the flight schools near my new home has a popular LSA, the Van’s RV-12iS, available for rental. The idea that I could just walk up and start flying it safely and efficiently is just plain wrong. Evidently the flight school has had a lot of customers who thought that, and they warn everyone to expect a five-hour checkout. It’s not a Taylorcraft. There are lots of systems. Plus, it’s a strange (to me) airplane, with a strange (to me) engine, at a strange (to me) airport, flying with a strange (to me) CFI. That is much more challenging than some of the simulator training I’ve had, which modeled the same airplane I’d been flying with the same engines at what quickly became a familiar airport with instructors who became friends.

One thing you can do to make the airplane less strange is to really study the pilot’s operating handbook (POH). Despite the light weight, reduced power and slower speeds, the RV-12 is a very complicated airplane. There are two flavors of RV-12, the iS and the ULS; the former is fuel-injected, the latter is carbureted. Since I’ve been flying the 12iS model, I’ll focus on it.

Software is the set of instructions that tell a computer what to do. My mother worked in software before I was born, so I may have more reason to think about it than others. And think about it I do. For her, software meant connecting plugs and throwing switches. When I started writing software, it was in “assembly language,” manipulating individual bits.

Modern airplanes depend on good software, and good software depends on good developer tools and good developer attitudes. Some developers use two or more teams to develop software with the same functionality, but some worry that since there is a standard computer science curriculum, these teams might make the same mistakes.

Pilots are pretty much in the dark about software development and have to trust the certification authorities to monitor it even as Boeing’s 737 MAX failures call that process into question.

The RV-12 is heavily software dependent; in that way it’s no less complex than the latest Gulfstreams or Falcons. The RV-12 may only fly in visual conditions, but can be flown at night. I have not decided whether I will do so.

POWERPLANT

Start with the Rotax engine. A big difference between my old Taylorcraft and the RV-12iS is that the Rotax is partially air-cooled and partially liquid-cooled. I expected to find a diagram of the cooling system, but all I could find was “Coolant—Level Check” and a checklist for abnormal coolant temperature. I’d like to know more.

The engine’s normal operating speed is 5000 rpm, and the maximum power setting is 5800 rpm. There is a reduction gearbox, so the propeller spins at a more reasonable speed. Importantly, rotating the propeller the wrong way can damage the gearbox. And that’s important because the procedure for checking oil level requires turning the prop by hand to engage the oil pump.

The RV-12iS does not use magnetos. It has two separate electronic ignition systems instead. The engine needs electricity to keep going, so it has two generators. I was pleased to see that the checklist calls for testing each separately. There are two Rotax computers, on separate buses, that distribute electrical power to the separate ignition systems.

AUTOMATION

My Taylorcraft had no computers except for a portable GPS whose battery life was less than its fuel endurance. The iPad had yet to be invented. This RV-12 has a Garmin 3X EFIS. My instructor said that some people really struggle with it, but I have flown thousands of hours with Garmin systems and found the transition pretty easy. Of course this system has its quirks, but the basics stay the same. Systems like this include all of the engine data, so handling a screen failure is important. Luckily, it’s easy to transfer data to another screen, as it should be.

Computers can do amazing things, but as anyone who has had to do a hard power reset of a cellphone or laptop knows, they can fail. An otherwise unnoticed electrical glitch—cosmic ray?—can change a single bit’s value from 0 to 1 or back, making everything fail. Backup is essential.

I printed out a copy of the electrical system schematic. For me, the paper schematic and a few colored pencils is the best way to learn a complex system. You may have your own method, but you have to have a method. This revealed something I still don’t understand: both fuel pumps are on the same generator bus. The other bus can feed this one. If Bus A fails, admittedly a very rare event, the engine will stop.

If the airplane had other systems I would print out their schematics and start tracing the flow of fuel or hydraulic fluid or electrons with the colored pencils. Retractable landing gear can generate a big sheaf of papers, since the best POHs have separate diagrams showing the system in various positions: up, down, in transit, etc., with electrical, hydraulic and mechanical components. Plus there can be another schematic showing the abnormal extension configuration. This does not apply to the LSA types, which typically have fixed gear, but it’s a good habit.

One aspect of learning a new type is comfort, especially of the pilot seats. If your arms are in an uncomfortable position, your arm muscles will be tense. With tense muscles, you won’t be able to hold the stick or yoke lightly and will miss out on a lot of control feedback and feel.

That makes it much more difficult to trim the airplane, and trim is a key to smooth flying. Some extreme conditions require flying with bizarre trim conditions. For example, I used to do a lot of (authorized) low-level flying. On those flights I trimmed the airplane a little nose-up, so if I got distracted it would start to climb, there being little room to descend.

The opposite side of this is that if there is a trim problem, like a runaway, your hands will be full. Some airplanes have a trim-in-motion warning so you can catch this problem before it literally gets out of hand. Lighter airplanes can be flown when out-of-trim. But it’s hard to fly them well.

THE AIRFRAME

The RV-12 airframe has two areas with potentially catastrophic problems: the canopy and the spar pins. My instructor was good about showing me how the canopy latched and reminding me not to leave the canopy open when the airplane is unattended. I was accustomed to being aware of the canopy from glider flying. For many transitioning pilots, though, this is a new concept.

The RV-12’s wings are removable, and there are spar pins on either side with an electrical warning if a pin is not properly engaged. Unlike in some gliders I’ve flown, the pins are easy to see during preflight inspection. Again, I was used to this procedure from the glider world. Gliders are regularly taken apart and put back together, and after putting it together, it is important to do a positive control check. This takes two people, one to work the stick and rudder pedals and the other to put a little resistance on the control surface to make sure that the attachment is correct. During glider competitions, the helper signs his or her name to the glider. I can’t imagine that the RV-12 or any other aircraft you can take apart would demand less rigor.

THE FLYING

This airplane is fun to fly. It is light on the controls and easy to keep coordinated. Stalls and slow flight had no surprises. The castering nosewheel saves a lot of weight, but it means that the pilot has to think ahead a little more because steering while taxiing is done with brakes. But shouldn’t pilots always think ahead while taxiing?

There is no manual trim, and for me the control-stick buttons weren’t placed where my hand naturally holds the stick. The airplane’s pitch trim changes when flaps are extended; in the RV-12, the flaps are controlled by the pilot’s right hand, and the trim is controlled with the left, which is pretty convenient. By contrast, most Cessna singles and Piper Cherokees are designed so that both flaps and trim are manipulated with the right hand, which means some muscle must be applied during flap extension.

The RV-12 has flaperons: the flaps are the whole trailing edge of the wing. The aileron function moves one side or the other up or down from that new neutral position. This is not noticeable in flight.

THE MONSTER

We pilots are travelers, but we don’t have to confront a monster like the Sphinx in order to proceed. And there’s no riddle to puzzle about. You can pass any quiz on the airplane just by studying its systems. Large or small, learn your airplane, learn its systems, learn its avionics and learn how it handles throughout the envelope.

Jim Wolper is an airline transport pilot and retired mathematics professor. He’s also a CFI with single-engine, multi-engine, instrument and glider ratings.