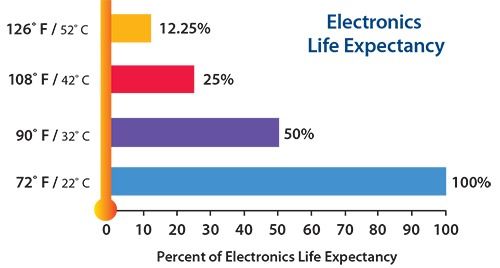

Excessive heat “kills” integrated electrical circuits, the kind found in modern avionics. Unlike many other electronic devices, avionics also may be exposed to sunlight filtered only slightly by a transparency. Combining the two sources—as when on the ground on a hot, sunny day, engine running and with all the electrical equipment active—is fairly common. While extreme cold temperatures can play havoc with avionics—for example, display screens may not work correctly—heat is the more pernicious threat. The bar graph at the top of the opposite page, adapted from the August 2017 issue of sister publication Kitplanes magazine, offers an estimate of life expectancy for modern avionics.

Not convinced? Consider the following statement from FAA Advisory Circular AC 23.1311-1C, “Installation of Electronic Display in Part 23 Airplanes”: “Electronic systems reliability is strongly related to the temperature of the solid-state components in the system. Component temperatures are dependent on internal thermal design and external cooling. In evaluating the temperature environment, consider the additional heat generated by the equipment, especially in a location where airflow is restricted.” In fact, cooling fans may be required equipment.

OUTSIDE AIR SCOOPS?

Recognizing the need to cool older, radios, many aircraft were built with air scoops to funnel/direct outside ram air to promote cooling. While this method worked, today it is regarded as inadequate for maintaining the cooling needs of modern digital avionics for at least two reasons. First, avionics cooling is most needed on the ground and not moving on a hot summer day with little to no ram airflow coming in from outside air scoops. In such conditions, it is not unusual for avionics equipment to reach an operating temperature of 150 degrees F.

Contributing is the vertical stack of avionics equipment commonly found in many aircraft, which exacerbates the heating by creating what is referred to as a “chimney effect”—the rising heat from avionics equipment within the stack is potentially cooking electronic circuitry mounted above.

Second, outside ram air can blow dirt and moisture directly onto expensive avionics equipment, leading to damage and failure. A better avionics cooling solution was needed.

AVIONICS COOLING FANS

Enter the avionics cooling fan. As typically employed in general aviation aircraft, they are a relatively inexpensive and practical method for keeping avionics components cool. These small, high-rpm fans direct air flow, measured in cubic feet per minute (cfm), to the avionics equipment. Not all avionics fans are created equal, though: A particular fan with higher output may be sufficient to meet the cooling requirements of avionics equipment, while a different fan, generating a lower cfm output, may be insufficient for cooling the same equipment.

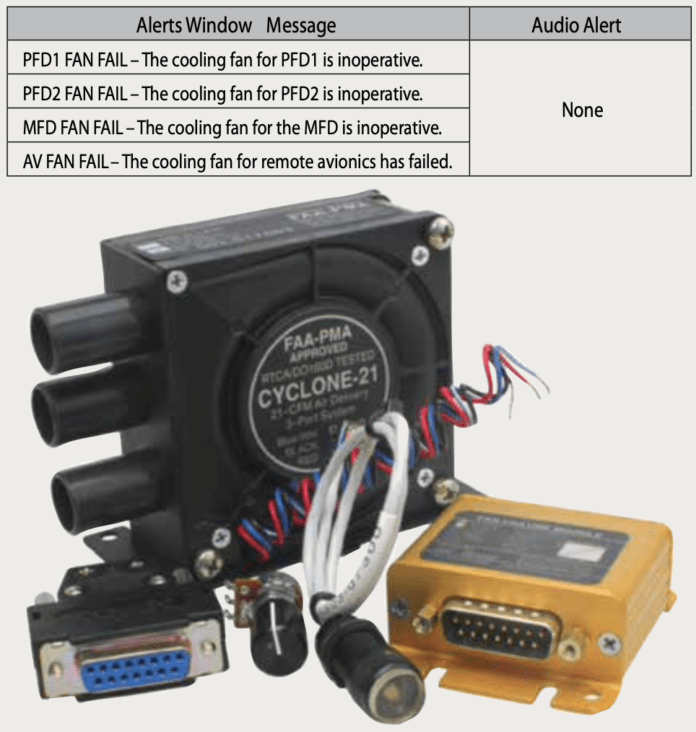

Some fans have a single output port for cooling one radio while others have multiple output ports and can cool an entire stack of avionics equipment. For example, one multi-port avionics fan depicted on the opposite page can generate 21 cfm and is capable of cooling several avionics components. Some installations can provide warnings of fan motor failure. By using the proper avionics fan to generate the requisite air flow as recommended by the avionics manufacturer, the operating life expectancy of the avionics equipment can be prolonged.

It is important to understand that digital avionics must be kept cool, dry and clean while in use. An avionics cooling fan is installed in such a way that the air is drawn into the fan from inside the cabin area, not from outside the aircraft like outside air scoops. In turn, the fan blows clean and dry air onto the avionics for cooling purposes.

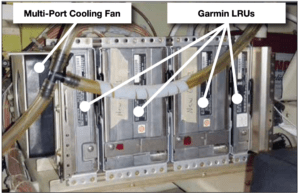

GARMIN G1000 COOLING FANS

Garmin incorporates cooling fans into many of their avionics systems. For example, avionics like Garmin’s GNS 430 (but not the GNS 530) have built-in fans, but their primary purpose is to cool the display and not move heat away from the chassis. Garmin’s newer GTN series does incorporate a chassis-cooling fan. Some line replacement units (LRUs) used in the G1000 system, like the primary flight display (PFD) and multifunction display (MFD) for example, are provided with a built-in or external cooling fan. Built-in cooling fans are not unique to Garmin; other avionics manufacturers employ such fans, for example the Avidyne EX 500 system. The G1000 system, as used in Cessna 172S Skyhawk SP and 182T Skylane, for example, has two primary cooling fans external to individual avionics components, a forward and aft avionics fan. The forward fan is mounted under the glare shield and behind the MFD; the aft fan is mounted on the rear wall of the aft cargo bay. Both cooling fans have vents to take in cabin air that, in turn, is directed to the avionics equipment.

The LRUs cooled in the forward avionics area by the forward avionics fan include the PFD, MFD, audio panel and engine airframe interface. This interface receives and processes signals from engine and airframe sensors. Driven by the engine airframe interface, the engine indicating system (EIS) shown on the MFD displays engine RPM, manifold pressure (on the 182), fuel flow, oil pressure and temperature, exhaust gas temperature, cylinder head temperature, vacuum pressure, fuel quantity and an electrical section indicating volts to the main and essential electrical buses and amperes (charging and discharging) of the two batteries.

The LRUs cooled by the aft avionics fan include the attitude heading and reference system (AHRS) air data computer (ADC), the transponder and two Garmin integrated avionics (GIA) units, each of which contain a communication radio, navigation radio and GPS receiver. The AHRS is used for displaying the attitude indicator, heading indicator (combined with information from the magnetometer in left wing), rate of turn indicator and slip-skid indicator. The ADC is used for displaying: outside air temperature (OAT), airspeed indicator, altimeter and vertical speed indicator.

Most of us these days are flying with a consumer-grade tablet computer running the electronic flight bag application of our choice. We’ve gotten dependent on them for our charts, traffic, weather and monitoring our position. They’re not perfect devices, however, and just like our installed avionics, can get hot, for many of the same reasons. Some tips for keeping them cool:

*Keep your tablet out of direct sunlight, especially when in use but also when the airplane is parked. Cover it with a chart (remember those?) when not in use.

*Adjust cabin air flow so it blows on or near the tablet.

*Use the tablet’s internal battery for power when able, since charging increases the device’s internal heat.

*Consider a mounting arrangement that incorporates a small fan.

CONTINUED AIRWORTHINESS

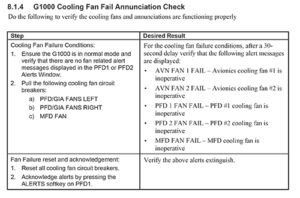

During preflight inspection of a G1000-equipped aircraft, it is important to verify the forward and aft avionics fans are operating properly. This is accomplished by turning on avionics bus #1 and listening for the forward avionics fan, and then turning on avionics bus #2 and listening for the aft avionics fan. The pilot may need to open the aft cargo bay door and place his/her head near the open door to hear this fan. Also, it is important to verify that the air inlets to the avionics fans are not obstructed by any objects (airplane covers, plastic bag, etc.).

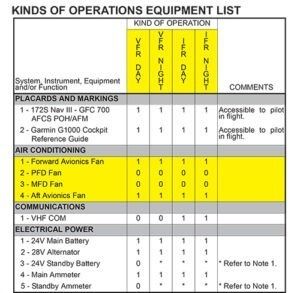

The consequences of an inoperative avionics fan and/or a fan with an obstructed air inlet are significantly decreased cooling air flow output, predisposing to overheating of G1000 avionics components resulting in popped circuit breakers and loss of G1000 functionality. Because of the overall operational significance of the fans, it must be understood that with an inoperative forward and/or aft avionics fan, the airplane is regarded as not airworthy and it must be grounded; it cannot be flown. An excerpt from a Cessna 172S pilots operating handbook is reproduced at the top of the opposite page and clearly notes that an inoperable forward or aft cooling fan is a no-go item no matter the type of operation planned.

The G1000 system is capable of displaying cooling advisory messages on the PFD. This is valuable situational awareness information for the pilot; it is important to know when avionics operating temperatures are too low or high. The text of the alert messages and their meaning is provided on page 8, via excerpts from the Garmin G1000 user manual. These advisories allow pilots to quickly understand and diagnose thermal issues that may be adversely affecting avionics equipment.

COOL AT ALL TIMES

Properly operating fans are essential for avionics cooling and airworthiness for many aircraft. While we’ve focused on the Garmin G1000 integrated flight deck for much of this discussion, other avionics systems will have similar requirements and considerations.

Regardless, it should be clear that sufficient cooling provided by avionics fans prolongs the equipment’s life expectancy and helps to minimize the probability of in-flight loss of your aircraft’s avionics functionality. “Staying cool at all times” not only applies to a pilot’s demeanor, but also to maintaining digital avionics equipment at appropriate temperatures—keep it cool.

Michael J. Banner PhD is a flight instructor in Gainesville Fla., a courtesy professor at the University of Florida in Gainesville and check/instructor pilot for the Civil Air Patrol. A CFII and MEI, he has 6000 hours flight time and owns an American Champion Citabria.