When compared against the opposite extreme—summer—flying in winter has a lot to recommend it. Because the air is cooler and therefore denser, aircraft performance is better. For the same reason—cooler air—flying in winter can be more comfortable than in the summer, thanks to the lack of air conditioning aboard the overwhelming majority of personal aircraft. And thunderstorms, typically the most dangerous weather of summer months, are rare—but not nonexistent—in winter. Of course, any kind of extreme can be a bad thing, or at least something demanding our attention. Winter flying is no different.

In fact, cold weather brings its own concerns and considerations to the task of safely getting in the air and back on the ground. For example, winter fronts and weather systems often feature low ceilings spread over a much broader area than we’d typically encounter other times of the year. Thanks to the colder temperatures, a lot more of the associated precipitation will be of the solid, frozen variety, either as it alights on something solid or shortly thereafter. When that something is an airborne aircraft, what happens next may not be fully within your control. But first you have to unlimber the airplane and get it airborne.

The main thing we want to accomplish when preheating an engine in winter is to warm its oil. Warm oil is thinner, flows better and can more easily get where it’s needed, the narrow spaces between precision-fit engine components, like bearings and crankshafts. Blowing some hot air on the cylinders from a torpedo heater for 10 minutes on a windy ramp isn’t going to get this done. Some options:

Warm Hangar

This is the gold standard, since it brings the entire aircraft up to a warmer, consistent temperature. Unfortunately, it’s also the most expensive and rare of the preheating options we typically have, especially as a transient. That said, even an unheated hangar brings dividends, since the aircraft is out of the wind and warm air directed at engine compartments isn’t swept away by the wind.

Installed Heating Elements

The next best thing is installing electric heating elements on the engine. Typically, these systems include bands around each cylinder base and a pad glued to the oil pan. Plug it into a wall socket with an extension cord and the engine gets warm. What could be simpler?

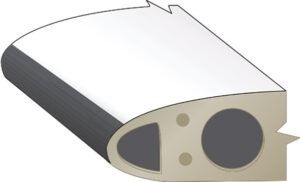

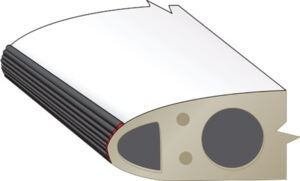

It does take some time, though, with an overnight often recommended. If the aircraft is outside, a long extension cord may be needed, and you would do well to install cowling plugs or even a blanket like the cute one here to keep the warm air where you need it.

Forced Air

The aforementioned torpedo heater or some other device to move hot air into the cowling has drawbacks. For one, it can create hot spots in the engine compartment, which might not play well with non-metallic components. Distributing the hot air where it’s needed most can be a problem, too, especially since the oil pan may not be easily accessible.

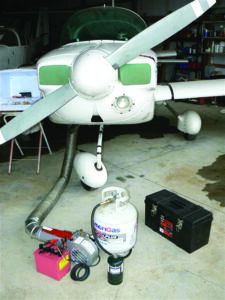

A propane-fueled heater doesn’t strike us as a device we’d want to leave running for a few hours in an unattended hangar, so electric ones seem like a smarter option. A system like the arrangement pictured here can seem cumbersome, especially to transport.

If All Else Fails…

If none of these options are realistic, you can always revert to what some bush pilots have been known to do: Drain the oil and keep it warm overnight, then put it back in the engine before starting. It’s inexpensive, but messy.

PREHEATING

Any discussion of winter flying worth its ink or pixels includes admonishment about preheating the engine and perhaps the entire airplane. This one is no different. How we go about it and precisely when we should be preheating are different matters, however. Ideally, we’d have the luxury of a heated hangar and can pull the airplane out and go flying on a moment’s notice. The real world we inhabit rarely works that well, sadly.

We preheat piston engines and their airframes to help minimize wear as the various moving parts start up and warm to their operating temperatures. The main thing we want is to warm the engine oil so it will flow better in cold temperatures. A multi-viscosity oil can be ideal in winter because it behaves more like a lightweight oil when cold yet lubricates like it’s heaver when warm. On those occasions when the destination is considerably warmer than the departure point, we don’t have to change to a lighter oil.

In the meantime, the various alloys in our engines have different rates of expansion and contraction. As they warm up, especially with cold oil trying to flow throughout the engine, it’s more likely unlubricated metal-to-metal contact will occur, increasing wear, something that can get expensive and might not bite us until taking off on a hot summer day a few years later.

Preheating the engine is a seasonal thing, of course, and one question that always pops up involves when to preheat. In other words, how cold does it have to get before preheating is “required”? As with so many aviation topics, it depends. Both Continental and Lycoming have published recommendations for the temperatures at which preheating should be considered.

For example, Continental’s service information letter SIL 03-1, “Cold Weather Operation – Engine Preheating,” states, “Preheating is required whenever the engine has been exposed to temperatures at or below 20° Fahrenheit / -7 degrees Centigrade (wind chill factor) for a period of two hours or more.” The same document includes recommended procedures for when temperatures are between 20 and 40 degrees F, plus how to use forced-air and engine-mounted heating systems.

Lycoming has this to say about the temperatures at which preheat should be applied: “For most Lycoming models, preheat should be applied anytime temperatures are at 10˚ F or lower. The exception to this rule is the 76 series models that include the O-320-H, and the O/LO-360-E. These engines should be preheated when temperatures are below 20˚ F.” Unlike Continental, which recommends procedures for different heating systems, Lycoming adds, “There are specific guidelines in Lycoming service instructions which establish when preheat should be used, but how much, or the method of preheat is generally left to the good judgment of the pilot or maintenance person doing the preheating.”

Our personal preference is to preheat when ambient temperature is below 40 degrees F. The sidebar on the previous page has additional details and some strategies to consider when preheating an engine.

Deicing boots have been around for decades, but only recently has there been definitive guidance on how and when to use them. The “old school” often taught that allowing ice to build on the boot before inflation was the most effective method. More recent research boils down to cycling pneumatic deicing boots early and often. According to NTSB Safety Alert SA-014:

- Leading-edge deice boots should be activated as soon as icing is encountered, unless the aircraft flight manual or the pilot’s operating handbook pilots specifically directs not to activate them.

- If the aircraft flight manual or the pilot’s operating handbook specifies to wait for an accumulation of ice before activating the deice boots, maintain extremely careful vigilance of airspeed and any unusual handling qualities.

- While icing conditions exist, continue to manually cycle the deice system unless the system has a provision for continuous operation.

- Turn off or limit the use of the autopilot in order to better “feel” changes in the handling qualities of the airplane.

PLANNING AND INSPECTION

Your preflight planning also should be different in winter months when compared to the summer. For one, you should be less interested in widespread convective activity and more interested in widespread low ceilings and/or visibility. You may still find thunderstorms or “thundersnows” in the forecast, but they’ll be associated with frontal activity and relatively easy to detect and avoid. Winds may also be stronger in the winter. What do these phenomena have in common? All of them, individually and especially together, should force us to take a close look at fuel requirements and surface conditions.

You’ll want options, both for fuel stops when headwinds prevail and for alternative plans when we need to go somewhere else. That means spending some extra time looking at your planned route and where you can go in a pinch. A key thing to consider when comparing summer versus winter flight planning is runway condition. For example, Class C Regional is more likely to have snow-removal equipment—and to have used it recently—than nearby Nontowered County, all else being equal. And inclement weather can play havoc with fuel deliveries to your destination or any divert facilities along the way. Calling ahead can save lots of time, energy and frustration.

You also want to think about terrain as part of your planning. Wind blowing over a large body of water typically can be a snow factory, so if you’re planning on being downwind of that big lake, think about the possibility of getting snowed in and the impact on your schedule. Think also about your options in winter over, say, Lake Michigan. You may accept the 10 or so minutes you’ll be out of gliding distance from land if the engine quits in July, but what about February? A flotation device alone won’t help much.

Finally, your preflight inspection won’t be much different than in the summer. There are two things you’ll want to keep in mind, however. One of them is pitot heat, something you should pay more attention to checking in winter than in summer. Another item is that there must be absolutely no snow, ice, frost or other contamination on the airplane before takeoff. While you may enjoy better performance in winter because of the colder, denser air, a shorter ground roll won’t matter if the airfoil can’t produce lift.

IN-FLIGHT ICING

Which brings us to in-flight icing. The vast majority of the airplanes we fly aren’t approved for flight in known icing (FIKI) conditions and have no real anti- or deice capabilities. It’s rare for a piston single to be FIKI-equipped, but more common for a piston twin. Turboprops and jets are a different question, of course, and likely have a different decision tree to determine if taking on icing is legal. But it shouldn’t matter, since no airplane is certified to sit in airborne icing conditions for an unlimited period.

We would suggest the typical piston single has no business remaining in known icing conditions, regardless of its certification. It simply doesn’t have the power—whether electricity devoted to running TKS pumps or thrust to overcome the additional weight of accumulated ice—to dally once the stuff is identified.

We’d also suggest your planning should have informed you of where the ice is—in both the horizontal and vertical dimensions—and where you can go or stay to ensure you’re out of it. While we’re at it, you’ve reviewed the documentation for the de- and anti-icing system aboard your airplane, and know how to service it and test it on the ground, plus use it and troubleshoot it in the air if the need arises, right? For example, you know that activating deicing boots early and often is recommended, right? See the sidebar on the opposite page for more.

PERSONAL EQUIPMENT

Air conditioning is perhaps the most common creature comfort we give up when flying the typical personal airplane. Ironically, heat can be the other. Cabin heating depends on creating and routing warm air, and everything about flying in cold weather makes that difficult. Poor door and window seals, inadequate ducting and lack of insulation all conspire to rob heat generated by our (mostly) air-cooled engines. And that presumes our twin’s combustion heater works. It also presumes the heat system itself isn’t trying to do us in by routing carbon monoxide into the cabin. A good CO detector should be part of your equipment in cold weather.

Many of us carry some kind of survival or signaling gear in the event “something happens.” That gear always should be optimized for the season and terrain, though carrying sleeping bags and a tent might be extreme (and unsettle your passengers). Still, loading some warm blankets for the back of your Bonanza is a good idea, along with battery-powered hand or foot warmers in extreme situations. You might be positively toasty up front where the sun and heater vents are, but back-seat passengers may not be sharing the warmth.

The cabins we fly in often are relatively tight-fitting when all the seats are filled, and especially when everyone’s wearing heavy clothing. Layering is always recommended, especially if you happen to be flying from warm to cold areas, or vice versa. Mainly, however, if you have to evacuate the airplane on the ground for whatever reason, it’s likely you’ll get out of it only with what you’re wearing. While you might enjoy a shortsleeve environment at altitude, you could need a parka on the ground. Plan accordingly.

TIMING IS EVERYTHING

Our final tip involves the relative lack of daylight in winter months when compared to summertime. You may be accustomed to leaving work, flying to Grandma’s house and having an hour or two of sunlight left in the summer, but you’ll typically have to leave earlier in the day for that to happen in winter. So, at a minimum, you’ll need to be night-current if you plan to carry passengers (and it’s not a bad idea even if you’re solo).

At the same time—see what we did there?—night flying increases our risk of controlled flight into terrain (CFIT) and the likelihood of falling victim to darkness-related optical illusions. If you haven’t flown at night in a few months, review some of the resources available, like the Pilot’s Handbook of Aeronautical Knowledge, and/or get some landings under your belt.

Finally, the lack of daylight can affect various services you might expect. For example, the FBO at Smalltown Municipal might be open until 9:00 pm in the summer, but close at 6:00 in winter, possibly eliminating fuel availability. It’s also unlikely a runway-closure Notam would be issued at that same airport until late morning if an overnight storm dumped enough snow to be a factor. Of course, the snowplow driver may not be able to get to the airport until someone else plows them out.

Flying in cold weather isn’t fundamentally more or less risky than at other times of the year. It is different, though, and we can be sluggish to revise our tactical thinking, especially when flying long distances.