A beam the numbers for the towered urban airport, I dropped the landing gear, confirmed I had the appropriate down-and-locked indications and waited for my Debonair to slow into the white arc. Then, as usual, I positioned the flap switch to the down position, anticipating through long experience I was extending them to their full travel of 30 degrees. After confirming my position and anticipating the turn to base, I glanced out at the wing, as is my habit, to confirm flap extension. Instead, I saw the left flap just beginning to extend.

“That’s odd,” I thought to myself; “They’re usually fully extended by now.” I diverted my attention back into the cockpit, adjusted power and flew my left turn onto the base leg. Another glance at the wing and the flap position indicator confirmed full flap extension. The landing was uneventful.

Soon, my friend and I had finished our breakfast—the flight’s purpose—and were winging our way back to the friend’s local airport. That landing, too, was uneventful, with flaps fully deployed. Thankfully, they also fully retracted as I cleaned up the airplane. After checking out some classic airplanes and sweating off another pound or so of gross weight, I mounted up and headed back to home plate.

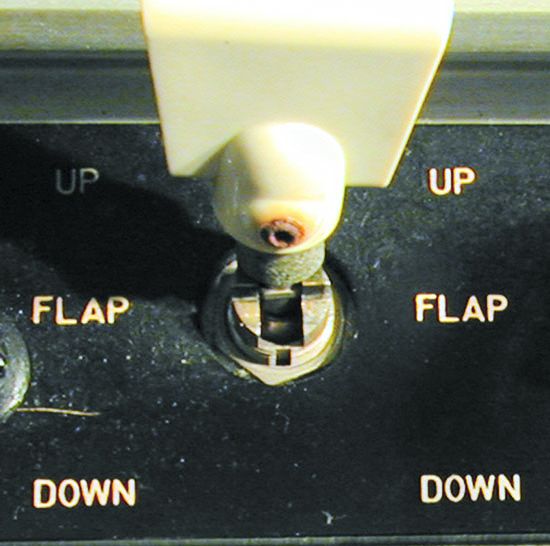

Soon, I was again on a left downwind with the gear down and locked, and reaching for the flap switch. Well within the white arc, I moved it to the full-down position, with my thumb on the electric trim switch, anticipating the coming pitch change. But nothing happened. I cycled the flap switch, but still nothing. I double-checked the circuit breakers, but every one of them was in their closed positions. Hmmm.

Home plate is not the longest runway—it’s marginal for takeoff in hot weather with a load aboard—but it’s more than adequate for landing with just me and some fuel. Without the additional drag and lift of deployed flaps, however, I extended my downwind a bit and planned for a flatter approach than normal. Soon, I was down and stopped, well before running out of pavement. I taxied to my hangar, secured the airplane and ambled off toward the air conditioning.

The next morning, I turned on the master switch and put the flap switch fully down. Nothing. Again, all the circuit breakers were closed. What a revolting development.

Because there’s no maintenance facility at home plate, I’m usually on my own when something with the airplane goes tilt. I make full use of FAR Part 43’s Appendix A, which details the kinds of preventive maintenance I, a mere owner/pilot, may legally perform. It’s important to note the FARs don’t prohibit someone who’s not a certificated mechanic from removing a component, just reinstalling it. But first I had to determine what was wrong.

I suspected the flap motor itself, since the rest of the system has been flawless, and saw an overhaul a few years back. That said, to my knowledge the flap motor has never been out of the airplane since it was new. I looked at some forum posts, images and videos on troubleshooting the Bonanza-family flap system, and Plan A became “remove the flap motor, send it out to a guy I know, and find someone to reinstall it.”

But the more I looked at how it’s mounted, the more convinced I became that a wag’s comment about Beech building the airplane around the flap motor was spot-on: It’s in the center of the airplane, with the wing spars bolted to it. It’s in one of those stand-on-your head locations: I can get it out, but I want someone who’s done this before to put it back in. Of course, that means finding a knowledgeable mechanic willing to travel to my location to do the reinstallation and paperwork. All of this popped up right before the annual EAA fly-in in Oshkosh, Wis., so good luck finding someone in their shop and willing to tackle this project before, say, Halloween.

Enter Plan B, which was to verify the motor was the problem. Out came the seats and off went the spar covers, exposing the motor and its wiring. After slicing off years-old shrink-wrap at the circuit’s knife connectors, I put a voltmeter on them. I got six volts instead of the expected 12-plus. Hmmm. That’s when I did a closer inspection, spying the green schmutz that’s a telltale sign of copper corrosion.

I sprayed some electrical contact cleaner on the connectors to remove the gunk, and got them bright and shiny. After reconnecting them, I turned on the master and hit the flap switch. I was greeted with an enthusiastic flap motor, happily spinning away to lower the flaps. Importantly, they came up, too. After verifying their operation several more times and securing the wiring, I pronounced the flaps fixed and reinstalled the interior.

To the extent there’s a moral to this story, one part of it is to practice no-flap landings every now and then, in accordance with your airplane’s limitations. Another part is that there are many tasks an owner may perform, especially low-skill, time-consuming ones like removing part of an airplane’s interior, that can help save money on maintenance and inspection.

A big part, though, is that older airplanes can develop mysterious maladies that may have simple solutions. An experienced mechanic usually can find and correct them without drama, but scheduling and ferrying require time and resources. With the tools, minimal talent—like me—and proper documentation, owners can save bundles of time and money doing their own troubleshooting before throwing up their hands, flying it to the shop and begging someone to fix it.

— Jeb Burnside