Beech C90A King Air

Worn Fuel Cap

The crew noticed fuel leaking from the right hand outboard fuel cap. Aircraft returned and the fuel cap was replaced with a new one. The aircraft has since flown 4.9 hours with no defects noted.

Part total time: Unknown

Beech 300 King Air

Unsecured Fuel Cap Lanyard

The crew noticed fuel streaming from the right main fuel cap. Maintenance found the fuel cap lanyard on top of the flange. Lanyard was removed, cap was secured.

Part total time: Unknown

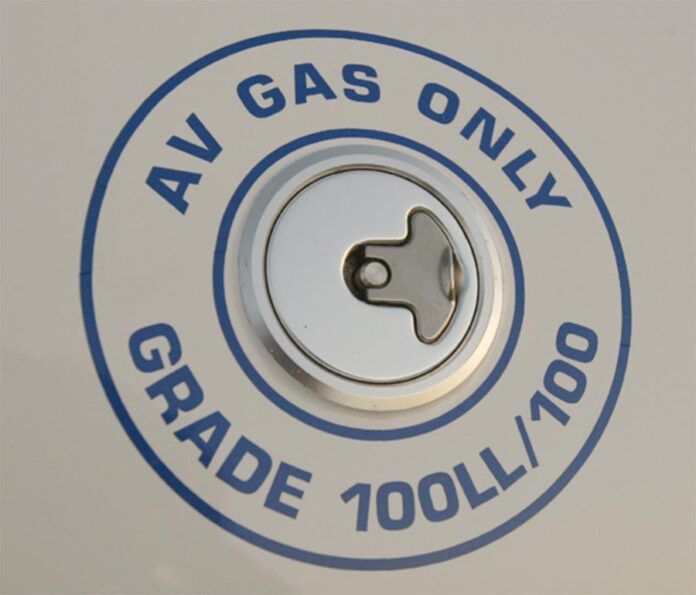

Cessna 172S Skyhawk SP

Deteriorated Gaskets

Found both fuel caps with gaskets under vent body deteriorated and squeezing out. Installed new caps.

Part total time: 198.0 hours

Cessna 185 Skywagon

Manufacturing Flaw

A design/manufacturing flaw in Hartwig “Monarch Premium Fuel Caps” installed on this aircraft means they will not seal due to incorrect placement of the fuel cap chain retaining tab in the filler neck. The cap threads bind to cause the cap to appear to be tight even though the filler remains open. If the aircraft is flown in this condition, fuel will siphon out of the tank. Some internet research reveals this problem has been seen by many in the field.

Part total time: 0.0 hours

Diamond DA40 Star

Broken Plastic Part

During a 100-hour inspection, a piece of plastic was found laying in the fuel filling area. After inspecting the fuel cap, the piece of plastic that was found was confirmed to come from the plastic part of the fuel cap.

Part total time: 993.0 hours

Piper PA-31-350 Navajo Chieftain

Missing Fuel Cap

Left inboard fuel cap missing. All fuel siphoned out of tank, causing left engine to quit. Fuel selector was switched to alternate tank & eng was successfully restarted. Due to the fuel loss, the fuel sender was not indicating properly. Located and examined the subject fuel cap; no defects were noted.

Part total time: Unknown

Van’s RV-12 Experimental

Plugged Fuel Cap Vent

Pilot experienced a 500 rpm drop on the takeoff roll and aborted. First flight after remedial work is fine; on second flight, same thing occurs. While the airplane is sitting in the sun, fuel begins escaping through the vent. Opening the fuel cap stopped the siphoning. Examination revealed the cap vent was sealed. Removing the sealant eliminated the issue. The manufacturer had changed the fuel system design and plugged the vent.

Part total time: 249.0 hours