Outside of large training organizations or fleet operations, there is little standardization of equipment, systems or procedures within general aviation. Toss in a few years among different owners and identical airplanes that rolled off an assembly line together 10 or 20 years earlier will vary wildly in their equipment, maintenance history and wear and tear. So despite having piles of experience flying a specific type, it may take a while to become familiar with a different example, even one bearing a consecutive serial number.

On one level, that’s a nice problem to have, since learning a new-to-us airplane’s capabilities and quirks helps ensure we can safely operate it and prepares us for the next one we fly after it. On another level, though, lack of standardization can leave us confused—or worse—when we expect one outcome but are confronted with another. Unmet expectations can lead to undesirable outcomes.

There is perhaps no steeper learning curve for a pilot than when acquiring an unfamiliar airplane. The first thing we want to do, of course, is fly it. But flying it is actually the last of a long list of things we should do to prepare for that first flight. Among so many other tasks we need to perform before that first flight is getting a thorough understanding of how its systems and procedures differ from whatever it is we’ve been flying. In our view, only production test pilots doing initial flights of zero-time aircraft have the luxury of not needing to research systems and procedures, even as they concentrate on other things.

If we have no experience with the aircraft type, risks increase. And as we shall see, if the aircraft has a questionable maintenance history, or if we ignore telltale signs of potential problems, those risks can skyrocket.

BACKGROUND

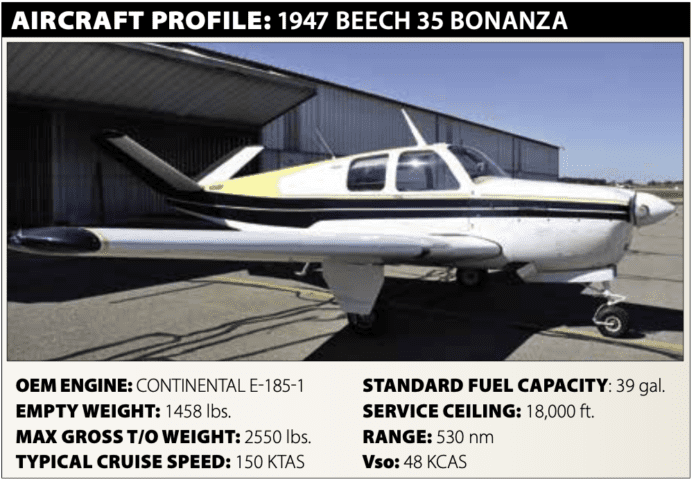

On March 6, 2021, at about 1217 Central time, a 1947 Beech 35 Bonanza was substantially damaged when it was force-landed following loss of engine power. The private pilot (male, 65) sustained fatal injuries and the private-rated copilot (male, 61) was seriously injured. Visual conditions prevailed.

The airplane had been recently purchased by the copilot and was being ferried to his home airport about 200 nm away. The pilot was helping the copilot on the flight. The day before the accident, an annual inspection was performed; the most recent annual inspection before had been conducted in 2012. The generator was not functioning.

Earlier on the day of the accident, the airplane’s standard and auxiliary fuel tanks were filled with 100LL avgas, for a total of 54 gallons usable. The pilot and copilot then flew the airplane in the traffic pattern, noting only the inoperative generator as an issue.

They then departed on the ferry flight, which was conducted with the retractable landing gear extended and with a rich mixture setting to help keep the engine cylinders cool. About 43 minutes into the flight, the left fuel tank was “depleted,” according to the NTSB, and the crew switched to the right fuel tank with no issues. They then switched to the auxiliary fuel tank and a total loss of engine power occurred. The crew tried different fuel selector positions as they attempted restarting the engine but without success. The copilot flew the forced landing, maneuvering the airplane through tree canopies until the airplane came to rest upright in a field.

The NTSB’s 2015 Safety Alert SA-021, “Is Your Aircraft Talking to You? Listen!” advises pilots and owners to “pay attention to signs of potential mechanical problems.” Among its recommendations:

• Resist the temptation to let external pressures, such as the desire to save time or money, influence you to fly an aircraft that shows signs of a potential problem.

• It is better to address a problem on the ground rather than risk having to deal with an emergency in the air.

• Remember the purpose of a maintenance diagnostic flight and stick to the plan. Be prepared for problems, and do not bring passengers.

• Ensure that the aircraft performs correctly after maintenance. If any indication of a potential problem persists, additional maintenance or a second opinion may be in order.

• Seek flight and ground training to ensure that you are prepared. During an actual emergency is not the time to find out that you are rusty on procedures.

INVESTIGATION

Post-accident examination confirmed flight control continuity and did not reveal any preimpact engine malfunctions precluding normal operation. The fuel selector was found with the handle between the OFF and LEFT positions, and pulled up in the hand-pump position about ¼ inch. Air could not be passed through any of the fuel selector ports in this position. It later functioned properly when air was passed through each port. Detents were not noted as the handle was rotated through the fuel tank positions. The placard depicting the positions and operation of the fuel selector was not observed in the wreckage.

Examination of the copilot’s cellphone revealed that, during the accident flight, at 1203, the copilot texted the airplane’s previous owner, asking how to position the fuel selector to the auxiliary fuel tank. Starting at 1213, the copilot received three text messages from his mechanic describing three positions for the fuel selector.

None of the three fuel tanks contained observable fuel. The auxiliary fuel tank and right-wing bladder were not breached. The left-wing fuel bladder was punctured by a fracture in the inboard wing rib, which produced a steady stream of water during a leak test. The puncture likely occurred during the accident sequence. There was no evidence of fuel spillage at the accident site, including odor or blighting.

The fuel lines appeared to be intact through the cabin to the firewall. No evidence of external fuel leaks was observed. The rubber fuel caps were dry and brittle, and the filler opening seats were corroded. The left fuel vent was obstructed at the anti-siphon wye; the inboard portion of the tubing contained fuel.

PROBABLE CAUSE

The NTSB determined the probable cause(s) of this accident to include: “A total loss of engine power due to the flight crew incorrectly placing the fuel selector between fuel tank detents, which resulted in fuel starvation. Contributing to the accident was the lack of a placard on the fuel selector, the lack of obvious fuel tank detents in the fuel selector, and the flight crew’s lack of understanding of proper fuel selector operation.”

The NTSB spent a fair portion of its report discussing the lack of a placard depicting the fuel selector’s available positions. Although the pilot’s operating handbook included a diagram showing the placard required to be installed on the fuel selector valve, no placard was found. A service bulletin advising of no-flow conditions when the selector is positioned between detents was not complied with.

Strapping on a 70-plus-year-old airframe that hasn’t been regularly inspected isn’t for the faint of heart, especially when it has known deficiencies like an inoperative generator. And flying a new-to-us aircraft beyond gliding range of an airport without testing things like the fuel selector seems less than optimal. Ultimately, however, 54 gallons of avgas disappeared in less than 200 miles of flight. The NTSB’s report doesn’t adequately explain how and why.