While conducting flight reviews for two decades, I’ve noted a subset of informed pilots employing up-to-date concepts to properly manage the air/fuel mixture entering their piston engine. Other pilots—probably because they were initially trained that way—leaned to peak exhaust gas temperature (EGT), no matter the engine power setting, and then enrichened it by 50 degrees F. Others merely set cruise power and pulled back the mixture about an inch and left it there. And, of course, another subset refused to lean the mixture at all, sometimes stating it was “too complicated.”

Except for the first group of pilots, the rest ignore that properly managing the engine’s mixture can limit cylinder head temperatures (CHTs), has vital implications for fuel economy and engine longevity. The trick is understanding that a full-rich mixture may be most appropriate in some operations and lean of peak (LOP) EGT may be best in others.

MEASURING CHT AND EGT

Modern engine management demands a modern engine monitor, one using thermocouples to measure each cylinder’s EGT and CHT, and then displaying the live data to the pilot. The legacy instrumentation in older airplanes—unless it’s been upgraded with a modern monitor—often provides CHT for a single cylinder and/or one EGT probe mounted in the exhaust pipe.

Both values are used in modern mixture management: Lean to the hottest peak EGT, and then further adjust the mixture to the rich or lean side, as desired. Then monitor CHTs to determine if the mixture setting is achieving the desired engine temperatures and to help warn you if the mixture setting changes. Once the mixture is set to your satisfaction, note the fuel flow value. Any change in fuel flow also will change the relative position of the mixture to peak EGT, which may require resetting the mixture. If this happens frequently, it should be diagnosed.

WHY MONITOR CHT?

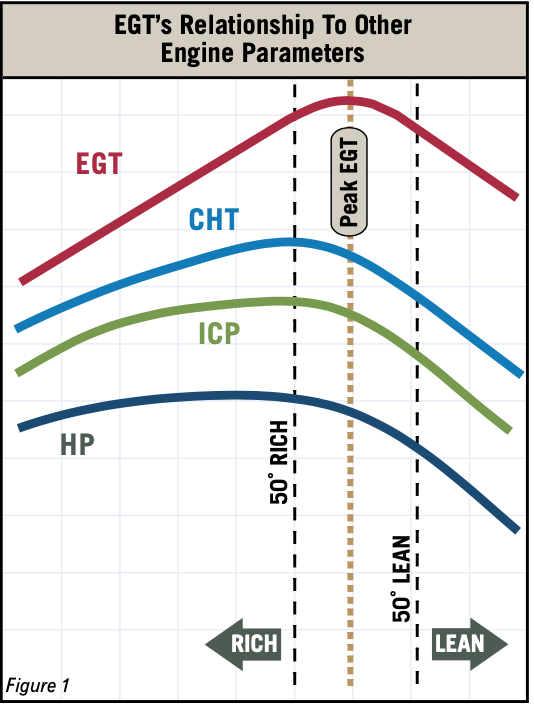

Cylinder head temperature can be a proxy for internal cylinder pressure (ICP), a parameter assessing the stress on a cylinder. Because ICP measurements are not provided, pilots rely on changes in CHT to infer changes in ICP, and for our purposes can be directly correlated. As Figure 1 at left describes, when the mixture control is enrichened from peak EGT for greater fuel flow, EGT immediately decreases while CHT and ICP increase slightly. Both CHT and ICP peak at 50 degrees F as the mixture is enrichened. This mixture setting—50 degrees rich of peak EGT—places the most stress on the cylinder. It also generates the most power, although further enrichening the mixture results in a fairly flat HP curve. Conversely, as the mixture is leaned from peak EGT, for less fuel flow, all three parameters—EGT, CHT and ICP—decrease.

It’s an article of faith that instructors who teach their students to lean to 50 degrees rich of peak EGT (ROP) learned to fly piston-powered aircraft in the military—or were taught by someone who was in the military—before jet aircraft began to dominate. The military had plenty of engines and people to change them.

THE RED BOX

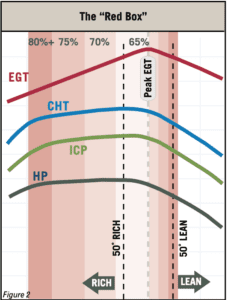

Figure 2

“Minimizing stress is a key to longevity,” a maxim that applies to humans as well as aircraft engines. Operating an engine at excessive CHT/ICP is stressful and can shorten its life, increasing the risk of in-flight engine failure. This condition alludes to operating an engine within the “Red Box,” a term coined by the team at General Aviation Modifications, Inc. (GAMI), when developing their aftermarket balanced fuel injection nozzles.

The Red Box, depicted at right in Figure 2, is a conceptual model applying when abusive mixture settings are combined with high engine power settings (greater than 65 percent). It follows that reduced power settings—below 65 percent—do not create excessive ICPs or CHTs that can lead to engine damage. In other words, at power settings below 65 percent, you can place the mixture control anywhere you want relative to peak EGT and no harm will come to the engine.

As fuel flow is manipulated, EGT is primary to gauge where we are in the lateral, rich-to-lean range while CHT serves as a confirmation. The area enclosed within the box is represented by shades of red denoting various power settings: darker red to the left of peak EGT denotes higher power settings and greater potential for high CHTs and ICPs, while shading to the right of peak EGT represents lower ones with corresponding less engine-damage potential.

Because CHT and ICP correlate as a function of fuel flow, CHT can be used to determine whether or not the engine is operating within the Red Box. Combining CHT data with EGT data for each cylinder provides valuable engine operating information for leaning. Since EGT can change much more quickly than CHT, it is preferred over the latter when we want to know how the engine is reacting to adjusting the mixture.

LEANING FOR ENGINE PROTECTION

In cruise flight and at higher engine power settings, LOP EGT operation has becoming the norm and modern method for well-instrumented airplanes with induction systems that support it. This refers to using appropriately operating fuel injection systems in engines that are capable of providing relatively consistent fuel-to-air mixtures to each cylinder. This is achieved by employing balanced fuel injectors that more precisely meter fuel to each cylinder, a technique developed by GAMI. This allows all cylinders’ EGT to rise and fall more or less in unison as the mixture control is moved. The airplane should be equipped with a modern multi-cylinder engine monitor capable of displaying CHT and EGT for each cylinder, plus fuel flow.

There are three ways to exit the Red Box. First, exit to the left side of Figure 2 by operating well ROP. Second, you can exit to the right by operating LOP. Third, exit to the bottom by reducing engine power settings to below 65 percent. Importantly, a normally aspirated engine will do this for you as you climb. Our rule of thumb is that at any altitude above 8000 feet msl, a normally aspirated engine cannot develop more than 65 percent power. Thus, it’s common to run the engine at peak EGT in cruise flight at or above 8500 feet msl.

Choosing the well-ROP option results in excessive fuel burn, increased carbon deposits on spark plugs and valves and increased operating costs. Are ROP engine operations ever indicated? Yes, well-ROP operations should be employed during takeoff and initial climbout. Although a ROP mixture burns dirtier than LOP, it also yields more of the horsepower needed for takeoff and climbout.

Once established in cruise, the LOP option is advocated. By operating LOP compared to ROP, fuel consumption and operating costs are decreased and range is increased. Yes, horsepower is slightly reduced when running LOP, but the fuel savings and cleaner combustion events bring benefits the loss of six or eight knots pays for.

CONTROLLING CHT

Once the desired mixture setting is achieved, the pilot’s principal engine management task is to monitor CHTs. When cruising a typical air-cooled aircraft engine, open the cowl flaps to allow more air to flow through the engine compartment to cool it or close them, allowing less air in, to keep them warm. Typically, closed cowl flaps are the norm for cruise; open ones are desired for takeoff and climb to altitude, where power and heat output are higher and the flow of cooling air is lower.

Pilots should consult the airplane’s documentation for guidance on how to use cowl flaps. However, many POH/AFM documents allow what we consider an absurdly high CHT value. In our view, CHTs of 400 degrees F should be the upper limit, with 360 degrees or cooler much more desirable. As the charts accompanying this article attest, CHT also can be controlled by going to a well-ROP or well-LOP mixture setting, the exact setting chosen with the Red Box’s exit methods in mind.

SUMMARY

Properly leaning the engine and routinely monitoring CHT are essential for protecting it from excessive thermal stress, ensuring cylinder longevity and helping to prevent engine failure. Lean-of-peak operations are a safer and more modern method of limiting CHTs and bring with them greater fuel economy.

Michael J. Banner PhD is a flight instructor (CFII, MEI) at University Air Center, Gainesville Regional Airport (GNV), Gainesville Fla., courtesy professor at the University of Florida in Gainesville and check pilot examiner/instructor pilot at the rank of major in the U. S. Air Force Auxiliary/Civil Air Patrol.