It’s that time of year again in the Northern Hemisphere. For those of us rarely straying into the teens or above, airframe icing usually isn’t a thing until late fall. Nowadays, with the typical freezing level much lower than other times during the year, we’re much more likely to see it up close and personal. Let’s be clear: Airframe icing in any form poses a significant danger to personal aircraft. There’s some weather no aircraft should be in, and icing tops the list.

As we all should know by now, airframe icing’s effects are cumulative. In other words, as thrust is reduced, drag increases, lift lessens and weight increases. The results are an increase in stall speed and a deterioration of aircraft performance. In extreme cases, inches of ice can form on the leading edge of an airfoil in less than five minutes. It takes little more than a schmear of ice to severely disrupt the aircraft’s aerodynamics. My encounter with icing in an airplane not approved for it should be a cautionary tale.

BACKGROUND

The encounter dates back to a time when I was working as an air-taxi pilot and mechanic for a fixed-base operator (FBO) that also was a Piper dealer. So, the aircraft I flew were nearly new. It’s important to know that technology has come a long way since then and weather information was not as detailed as it is now. The internet was not in general use then, and there was no GPS or other means of IFR-approved long-range navigation for general aviation. Electronic instrumentation was unheard of in the piston general aviation community.

The infrastructure also wasn’t as good as it is today. There was limited ATC radar service and almost no coverage in outlying areas of mountainous terrain or low traffic. Position reports and full instrument approaches were common away from beaten paths.

Before this event, I had been traversing the Sierra Nevada range on oxygen in mostly clear skies at altitudes of 17,000 to 18,000 feet msl. The routing I would travel was in the area of Bishop and Mammoth, California, to destinations in Nevada. Mount Whitney and other high terrain is near to these towns along my route of flight. Occasionally, I would briefly pick up some light icing in the clouds during the climb from Modesto, but I was able to climb rapidly to get in the clear and wasn’t seriously impacted. Occasionally, I would stop in Mammoth for oxygen and fuel on the return trip due to headwinds and slower groundspeeds.

Ground deicing and preflight prior to a winter flight is extremely important. No amount of ice or snow on an aircraft is acceptable for takeoff. There have been many accidents over the years involving all types of aircraft attempting a takeoff with a contaminated airfoil. Even with light snow accumulation, you may think that it would blow away on takeoff, but that is not always the case.

Snow and ice removal from general aviation aircraft is a problem, as most general aviation airports are not equipped to deice aircraft like the larger commercial facilities, with boom trucks and heated deice fluid. There is an FAA-approved deicing fluid product (Ice Off) that is suitable for deicing fixed wing aircraft and can be supplied in small amounts. This fluid can be mixed and used in a garden sprayer or other pressure equipment as needed.

Never use unapproved products such as automotive anti-freeze, as not only does it not do the job, it can damage paint and plastic parts to include aircraft windows. Alternate removal methods include soft bristle brooms to move light snow, moving the aircraft into a heated hangar—the gold standard for deicing an airplane—or heated air. Melted snow/ice should not be allowed to enter flight controls and refreeze, disturbing balanced control surfaces.

FLIGHT DETAILS

It was a daytime air-taxi flight from Modesto to Bishop, California. I had been flying over this area on my way to and from central Nevada several times and only occasionally picked up a little ice in the Piper PA-34-200T Seneca II. I normally went up to around 17,000 feet msl to get to good VFR. But the winter weather that day was stormy. I was to take two passengers to Bishop for a court appearance.

On departure, ATC restricted my climb for traffic. Climbing out of about 8000 feet eastbound, the engines started surging. I recognized that the fuel flow indications were fluctuating, so I turned on the low fuel boost pump and the surging went away. I had activated the alternate air to the engines with no effect. I was IMC almost the entire flight and was flying single-pilot IFR with the autopilot disengaged due to the surging. The engines started surging again at around 12,000 feet, so I used the high boost pumps and the surging stopped. A Pirep reported cloud tops at 14,000.

I was picking up ice almost the entire time and didn’t realize what was happening when the engines first started the surging, although I could feel the yaw in the rudder pedals. All the windows were iced over except the vent at my left shoulder. I had to use the alternate static system and, later in the flight, the airspeed indicator became unreliable even though pitot heat was operating the entire flight. When I was finally allowed to climb to FL190 and got leveled off in the bright sunshine, I just barely touched the prop controls when the left engine quit, with zero fuel flow. Where I was, the minimum en route altitude (MEA) was 15,100 feet. I got the left engine feathered as the airplane started drifting down toward it single-engine ceiling of 12,000 feet. During the descent through 17,000 feet, I declared an emergency and turned back to the west, toward lower terrain. I went through and was below the 15,100-foot MEA for about seven miles, drifting down to the next MEA of 12,000, which I could hold onto.

I did not attempt a restart of the failed engine, as I didn’t want the propeller to come out of feather and increase drag if I wasn’t successful. I chose not to divert to Bishop, which was only 25 miles away, since weather there was two miles in blowing snow and a 15-knot crosswind. The approach was a VOR/DME affair, with high minimums due to terrain. I quickly discounted the possibility of a safe landing or a missed approach. Instead, I returned to Modesto.

The freezing level as I neared my destination was around 3000 feet and the ice started coming off in the warmer air. I elected to fly an ILS with a 10-knot tailwind, and then circle underneath an 800-foot overcast to land into the wind. I discovered that the single-engine configuration would not hold altitude in the downwind with the gear and flaps down. I had to bring them up and then put them down again on final approach. I landed uneventfully.

I suspect the surging and left engine failure resulted from ice blocking the fuel vents. After an extensive investigation on the almost-new airplane, nothing was found to definitely have caused the engine problems.

Each design accumulates and reacts to airframe ice differently, so the external signs you’re picking it up vary from type to type. Some, as at top right, first show ice on the outside air temperature probe. Others, bottom, on the windshield. Some tips on observing and dealing with ice:

- Clues that ice may be forming during level flight is a reduction in airspeed associated with an increase in pitch to maintain altitude. Check the windshield or other components in your view such as windshield wipers or antennas for icing.

- Disconnect the autopilot occasionally to physically check for sloppy control response as sometimes ice forming on the horizontal stabilizer, elevator or stabilator may lead to reduced flight control effectiveness, which would be masked by the autopilot.

- Precipitation static may impact communications with ATC and St. Elmo’s fire may be experienced during flight in moderate to heavy precipitation, which can be especially distracting at night.

- Icing will alter the normal operational parameters, such as increasing stall speed.

- When transitioning from the descent to approach phase, make minor configuration changes and select wing-flap position incrementally to ensure you have full control of the aircraft.

- If runway conditions allow, consider landing with less than full flaps to ensure positive control throughout the approach and landing.

AFTERMATH

This event highlights several operational considerations. The Seneca II I was flying obviously was not approved for flight into known icing. It didn’t have leading-edge boots—the technology of the day—a deiced windshield, propeller protection or heated fuel vents, among other features. Things it did have included two engines and turbocharging. It would have been a neat trick to get a normally aspirated piston twin to FL190, but the ability to get there and then drift down to the airplane’s single-engine ceiling required turbocharging. That I had two engines minimized the likelihood of losing all engine power, but in the event it was a near thing.

Good ice protection has trickled down over time even to piston singles, which these days typically use a “weeping-wing” system like TKS instead of pneumatic boots. Regardless, it’s extremely important to know how to operate the equipment. A boot-based system, for example, often must not be operated until a specific amount of ice has accumulated on the boot. Generally, the system operates to briefly remove an ice buildup and then deflates to allow for another buildup.

According to the FAA’s Aeronautical Information Manual (AIM) at para. 7-1-19: “A pilot can expect icing when flying in visible precipitation, such as rain or cloud droplets, and the temperature is between +02 and -10 degrees Celsius. When icing is detected, a pilot should do one of two things, particularly if the aircraft is not equipped with deicing equipment; get out of the area of precipitation; or go to an altitude where the temperature is above freezing. This ‘warmer’ altitude may not always be a lower altitude. Proper preflight action includes obtaining information on the freezing level and the above freezing levels in precipitation areas. Report icing to ATC, and if operating IFR, request new routing or altitude if icing will be a hazard. Be sure to give the type of aircraft to ATC when reporting icing.”

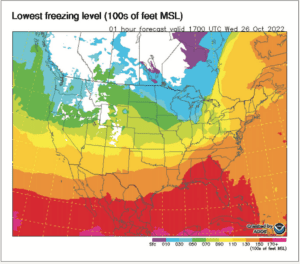

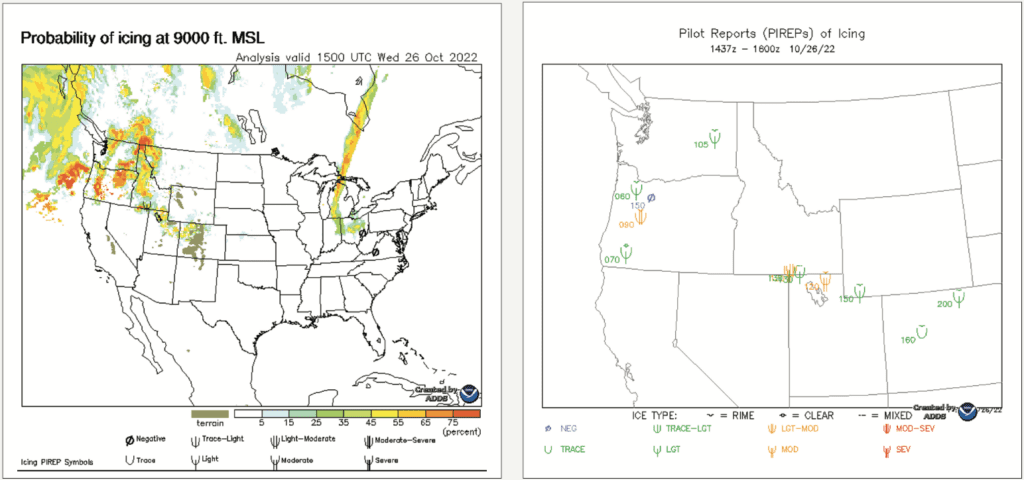

Just as you have to plan around thunderstorms in warmer weather, you should modify your planning this season for ice. The good news is that predicting it is much more accurate than just a few years ago, and the tools we use to evaluate airborne icing are better, too..

That said, those tools we use to self-brief airframe icing are similar to those we use for thunderstorms: They’re often color-coded, can cover wide areas and freezing altitudes can be extremely relevant. Some examples of those tools are at right and below. And as with weather radar, you want to avoid certain colors and welcome others.

Some rules apply to planning for ice. One, it’s a bad idea to rely on the absence of pilot reports of icing from aircraft in your vicinity, as airframe icing can vary with aircraft type and speed. Two, just because the aircraft you are flying is certified and maintained for flight into known icing conditions does not mean that prolonged operation in icing is safe or smart, no matter what you fly.

HAVE OPTIONS

I had few options because I was over high terrain. I couldn’t climb much higher, even on two engines, and there was little room beneath me to seek warmer air. As it was, I busted the MEA, but had already declared the emergency. Which brings up, don’t be shy about declaring an emergency, as an early declaration gives ATC a better chance of clearing traffic to accommodate you. When weather conditions encountered are so severe that an immediate deviation is determined to be necessary and time will not permit approval by ATC, the pilot’s emergency authority may be exercised.

I hope this narrative of my icing encounter in a non-approved airplane instills in the reader just how serious this situation was. Any encounter with icing in an aircraft not properly equipped requires immediate recognition and positive action to exit it.

Mike Berry is a 17,000-hour airline transport pilot, is type-rated in the B727 and B757, and holds an A&P ticket with inspection authorization.