One of my favorite aspects of winter is the peaceful calm after fresh snowfall. The snow softens all sound, and the undisturbed scene looks beautiful. Coincidentally, this is one of my least favorite things to encounter as a pilot. When I am flying, I much prefer the sight of snow removal equipment and clear blacktop. If you regularly fly in winter weather, you might be used to landing on something other than clear, clean pavement.

Contaminated runways incur several hazards. On takeoff, they can exert additional drag on wheels and tires, preventing normal acceleration to lift-off speed and dramatically increasing stopping distance in the event of an aborted takeoff. On landing, the reduced friction can result in overruns and other unintentional runway departures. Let’s explore what you can do about contaminated runways and what to look for.

BACK TO BASICS

There are a few advisory circulars that are worth reviewing if you want to brush up on contaminated runway operations. Much of the content in AC 91-79A (Mitigating the Risks of Runway Overrun Upon Landing) and AC 25-31 (Takeoff Performance Data for Operations on Contaminated Runways) references jet aircraft, but it is relevant to airplanes of all shapes and sizes.

Runways are either dry, wet or contaminated, as defined in AC 25-31:

Dry: A runway is dry when it is neither wet, nor contaminated. For purposes of condition reporting and airplane performance, a runway can be considered dry when no more than 25 percent of the runway surface area (within the reported length and the width being used) is covered by visible moisture or dampness, frost, slush, snow (any type) or ice.

Wet: A runway is wet when it is neither dry, nor contaminated. For purposes of condition reporting and airplane performance, a runway can be considered wet when more than 25 percent of the runway surface area (within the reported length and the width being used) is covered by any visible dampness or water that is 1/8-inch (3 mm) or less in depth. Note: A damp runway that meets this definition is considered wet, regardless of whether or not the surface appears reflective.

Contaminated: For purposes of condition reporting and airplane performance, a runway is considered contaminated when more than 25 percent of the runway surface area (within the reported length and the width being used) is covered by frost, ice and any depth of snow, slush or water. Expanded definitions of each type of contaminant are in the advisory circular.

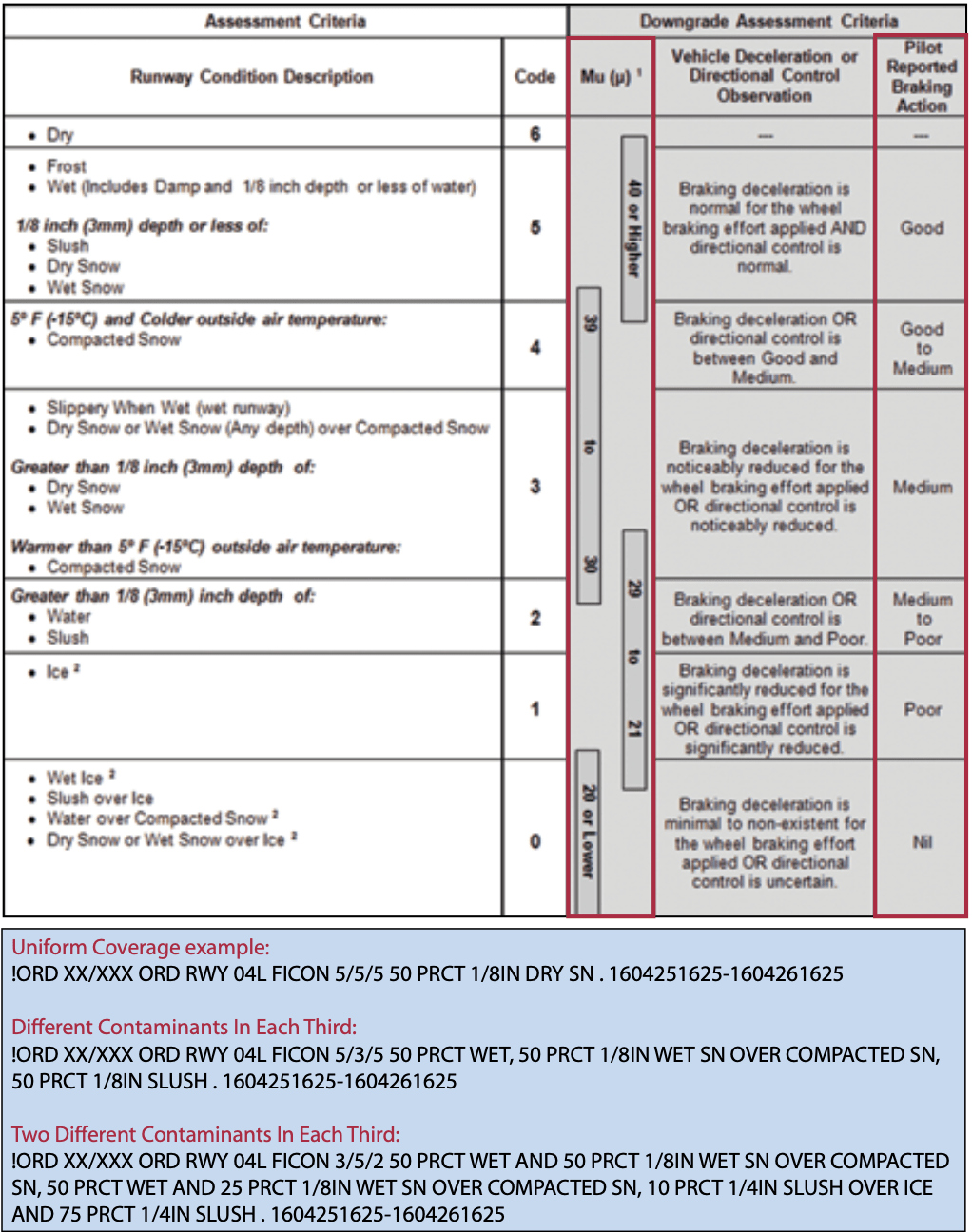

So now we have the book definitions, how does the translate to the real world? In 2016, the FAA introduced the Takeoff and Landing Performance Assessment (TALPA). This included the Runway Condition Matrix (RCAM), which airports use to define runway contamination levels. Reproduced at top right, the RCAM lists assessment criteria and the associated runway condition code.

The assessments range from 0 to 6, with 6 being dry and 0 being wet ice or other contaminants over ice that reduce the braking action to zero. Airports are responsible for disseminating this information to crews via Notam. Three examples of field condition (FICON) Notams are reproduced in the blue box at right, all of them for Runway 04L at Chicago’s O’Hare International Airport (ORD).

First, the runway is listed. Airports will typically only report the condition code on active runways, which helps with preflight planning. Next is the condition code itself. Each number represents the condition for each third of the runway. This is helpful especially when considering different phases of flight. For example, during takeoff it may be prudent to consider the first third, whereas on landing the midpoint and rollout may be more critical. Lastly, the actual contaminant is listed. Some manufacturers publish performance corrections depending on the contaminant, which can give the pilot a more accurate picture of expected landing performance.

Pilots are responsible for keeping a ton of information on deck, available to pull from our vast memory banks at the drop of a hat. If you are like me and not landing on contaminated runways day in and day out, the numbers and their associated braking performance may not be burned into memory. I personally saved a copy of the runway contamination matrix to my EFB. I review it whenever faced with contaminated runways and having it available during flight helps with rapidly changing conditions.

TAXI

One of the oft-forgotten discussions with contaminated runways is getting to said runway. Often runways are paved, deiced and sanded while ramps and taxiways are left behind. When starting up the plane, ensure the area in front of the aircraft is as clear as possible. There is nothing worse than the feeling of your aircraft creeping forward after engine start and jumping on the brakes only to have nothing happen. Once you begin taxiing, slow and steady wins the race. If you are flying a single-engine propeller plane, making as many turns as possible to the left allows you to utilize the left-turning tendencies rather than fight them. It may not matter much in a Skyhawk, but with the rising popularity of single-engine turboprops, it is worth mentioning.

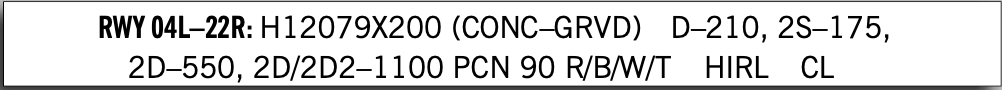

There is a lot of debate out there about grooved runways. Grooves help reduce the levels of standing water as the pavement floods or drains. While grooving does not eliminate hydroplaning, it can reduce it and create more contact between tires and pavement surface. According to ICAO, in the presence of water, totally worn aircraft tires experience better braking on grooved pavement than newly treaded tires on non-grooved pavement. Some aircraft manufacturers provide takeoff and landing data for grooved runways, but the majority do not.

Above is a snippet from the Chart Supplement entry for the John F. Kennedy International Airport (JFK), showing RWY 04L-22R is a grooved runway. Personally, I have never flown an aircraft that had any performance relief for grooved runways. If there was an option to land on similar runways and one was grooved and one was not, I would absolutely choose the grooved runway. Either way, it is still worth it to err on the side of caution and treat the runway as if it was wet regardless of its groove status.

TAKEOFF

There are several hazards worth considering when taking off on a contaminated runway. Many contaminants substantially reduce friction and braking action. Crosswinds create a higher risk of a runway incursion due to the reduced effectiveness of nosewheel steering and differential braking. Additionally, accelerate-stop distances can drastically increase. Crosswind technique is essential, and it is an excellent mitigation strategy to pick a decision point along the takeoff roll at which the takeoff will be aborted if liftoff/rotation speed is not achieved. It is critical to be aware of your takeoff performance, even on longer runways.

Certain contaminants, such as slush and dry snow, create drag and can prevent normal acceleration. Ironically enough, this can actually reduce your accelerate-stop distance: All that drag preventing you from accelerating helps in the event of an aborted takeoff. Again, a mitigation strategy for this is choosing a decision point. There is nothing more stressful than staring at the end of the runway (or the tops of a tree line) five knots below rotation speed and not accelerating. Unfortunately, unless your aircraft has numbers published for different contaminants, you will have to use your best judgment. On the flip side, until you take off, there are options. There is no better way of testing the runway than taxiing down it, and if there is any doubt there is always the option to delay or cancel.

LANDING

Landing is truly where the challenge comes when dealing with contaminated runways. Like all good things, flights must come to an end. We all prefer a greased landing with an uneventful taxi back to parking, but sometimes external factors make this a challenge. On the whole, the first step when intended to land in winter weather is to have a backup, and then a backup to the backup. Airports frequently close for snow removal, and step one is bringing as much fuel as possible for holding and diverting to an alternate, ideally with a long runway or less winter weather.

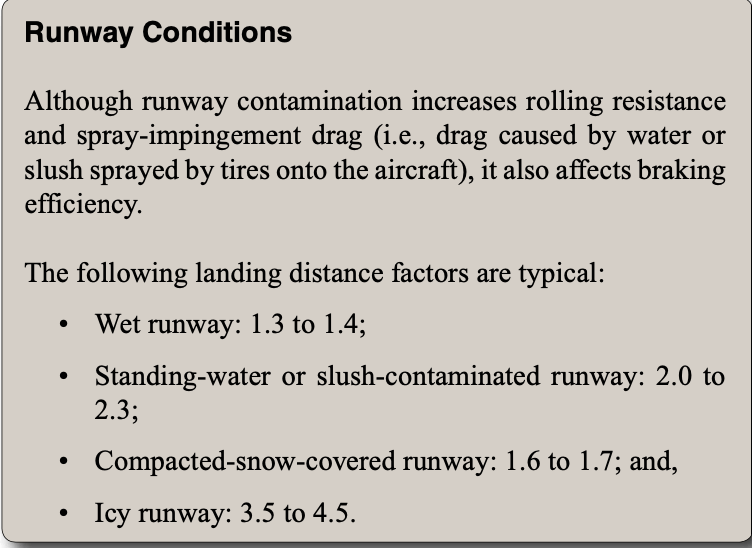

Landing on a contaminated runway has two major risk factors; overrun and runway excursion. For preventing overrun, it is critical to know your expected performance. If your aircraft does not publish numbers, the Flight Safety Foundation has some guidelines, reproduced in the text box on page 13.

What are your best risk mitigation strategies when landing on a slippery runway? Start by picking a touchdown point where you know if you are down and applying brakes, you will stop with runway remaining. Additionally, apply brakes as soon as possible after touchdown.

One of my biggest fears is flying into non-towered airports, at night, with snow in the area. I have experienced numerous flash freezes, where the temperature was warm enough during the day to melt the snow and leave the runway wet. As the sun goes down, the temperature drops to below freezing and that thin layer of water on the runway turns into a skating rink.

When it happened to me, I called in-range to an airport and line service said the runway was merely wet. Luckily, they checked again when I was on final and told me the airport was closed after the golf cart nearly slid off the runway. Long story short, if you land and the brakes don’t function, maybe it is time for a touch-and-go instead, if performance and terrain permit.

Another risk is a runway excursion. Just like on takeoff, crosswind control is imperative. In the event a tire locks up or the aircraft starts to drift, make the appropriate inputs without over-correcting. If you are fortunate enough to fly an aircraft with reverse thrust, it is an extremely effective tool but can cause whiteout conditions in winter weather.

Depending on how your aircraft is certified, you can calculate ground roll, total distance to clear a 50-foot obstacle or accelerate-stop distance. For landing, you may be calculating ground roll or total landing distance. Total landing distance factors in the aircraft crossing the threshold at 50 feet and on-speed, whereas ground roll is merely the stopping distance over the ground.

Based on recurrent training and flight reviews, too many pilots use extra speed as a crutch. To help prevent stall/spin accidents on final, pilots fly faster than needed. I flew Skyhawks, the 172R model, which has a published stall speed of 47 knots. Despite this relatively low stall speed, many applicants would approach the runway, fully configured, at 70-80 knots. This buffer, while it will typically prevent a stall, causes the exact scenario of a GA aircraft experiencing a runway overrun. All performance calculations are based on proper operation of the aircraft, including being on-speed.

ALL TOGETHER NOW

Flying in winter weather presents all sorts of challenges and using potentially contaminated runways is one of the leading culprits. Luckily, there are more resources available to flight crews than ever. The relatively new Runway Contamination Matrix provides objective information in a timely manner. While the method is not perfect, it is a significant improvement over the more subjective reporting used in the past.

Careful flight planning and proper technique make excellent mitigators. Calling the airport manager or FBO you intend on visiting is a great additional method of gaining information on current conditions.

Ultimately, the risk mitigation strategies used for any weather-related hazards work perfectly for contaminated runways. Personal minimums, if you use them, recognizing hazardous attitudes and maintaining proficiency are the most effective tools when landing on contaminated runways. Maintaining vigilance can prevent the dreaded slip and slide, allowing for our favorite ending, a non-eventful taxi to the ramp.

Ryan Motte is a Massachusetts-based Part 135 pilot, flight instructor and check airman. He moonlights as Director of Safety when he isn’t flying.