Anyone who’s taken more than a couple of flying lessons has been exposed to simulated failure of a single-engine airplane’s powerplant. For ab initio students, the first engine-out drill often is a demonstration that the airplane won’t fall out of the sky and that the situation can be managed to successfully get on the ground and walk away, even if you can’t use that particular airplane again anytime soon. As pilots gain more experience, certificates and ratings, the engine-out drill takes on much greater significance, and can even make or break a checkride or flight review. Pardon the pun, but that goes double for multi-engine airplanes.

Unfortunately, pilots often don’t take the drill seriously—I know I’ve been guilty of that—which ends up diluting its value as a training exercise in several ways. In fact, the engine-out drill has greater significance than many pilots acknowledge: It’s an important test of muscle memory, of recalling so-called bold-faced checklist items, of judgment and of airplane control. And depending on how and when your instructor initiates the drill, it may be completely worthless. That’s important, since the purpose of an engine-out drill is to practice what’s necessary to restart it and find a place to land if you can’t.

MEMORABLE DRILLS

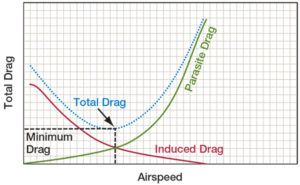

The first time my primary instructor pulled off the power and announced the engine had just failed, he walked me through the various steps I needed to take without using the checklist. As we descended at the Cessna 150’s best glide speed, he casually indicated a nearby field and told me to aim for it. He demonstrated the need to fly at the correct airspeed by slowing and accelerating while pointing out the vertical speed changes, and explained why we were clearing the engine to ensure it could make power if we ended up needing it.

About the time I was ready to add power and go around, he took the controls, added flaps, did a flow check confirming we were ready to land and put the airplane down on a grassy field. As we rolled out, I noticed a windsock off to one side—we had landed on a private turf runway my instructor had permission to use. That was my first revelation about engine-out drills—that there’s often a runway close enough to reach if you look for it.

Years later, I was checking out in a rental Cessna 172N Skyhawk. At that time, I probably had 100 hours or so in 172s, a fresh instrument rating and something of an attitude. I don’t remember all the details of what that instructor asked of me on the flight, but at one point the engine lost power and he announced an engine-out drill. I went through (most of) the memory items—mag switch on “Both,” throttle full, mixture rich, carb heat on. I didn’t bother to check the fuel selector, because who’d be crazy enough to shut off the fuel at 2500 feet over the Chesapeake Bay at night? The engine did not regain power. “Okay,” I said to the instructor in the right seat, “what did you do?” He reached down to the fuel selector and turned it from the “Off” position back to “Both.” The engine came back to life and I readjusted the power settings.

The lesson he wanted me to learn was to include the fuel selector in the immediate action items when the engine fails to produce power. I got the message, but I resolved not to fly with that instructor again, and haven’t.

The FAA’s commercial pilot airman certification standards break down the single-engine airplane simulated power failure into three major areas: knowledge, risk management and skills. According to the ACS, the objective is “To determine that the applicant exhibits satisfactory knowledge, skills and risk management associated with a power failure at altitude and associated emergency approach and landing procedures.” Highlights include:

Knowledge

Immediate action items and emergency procedures

Airspeed (best glide, minimum sink and effect of wind)

Stabilized approach

ELTs and other devices/ATC services

Risk Management

Consideration of altitude, terrain, obstructions, gliding distance, etc.

Flightpath planning

Airplane configuration

Low-altitude maneuvering, including loss of control

Decision-making, situational awareness

Skills

Airspeed (+/- 10 knots)

Airplane configuration

Landing area selection

Checklist usage

PROBLEMS

That episode highlighted for me one of the problems of the engine-out drill. For one, real-world engine failures rarely involve the powerplant suddenly stopping for no reason. If it does, it’s usually a result of something the pilot did or didn’t do, like forgetting to switch tanks, or switching to one filled with air. Instead, real-world engine failures often are more gradual, providing lots of warning to the pilot. Even more common are partial failures, where it’s obvious something’s wrong, but the engine is still producing some power. The engine-out drill is, however, an important skill, so there are certain rules involving training for it and demonstrating it to your examiner. The sidebar above has some highlights.

Another problem with the engine-out drill is that it rarely results in an actual off-airport landing, for obvious reasons. My first such drill, related above, is the exception to the rule, though enterprising instructors often contrive ways for the student to actually perform a power-off landing, usually back at home plate after pulling off power in the pattern. That’s more valuable than the typical descent to 200 feet or so followed by a go-around, but still isn’t the same as a for-real off-airport landing.

A third problem with the engine-out drill is that it can lead to an actual engine failure and/or reportable accident. Pilots generally accept that most training operations involve greater risk than straight-and-level cruising, but don’t always acknowledge the risk of combining reduced power settings and airspeeds with maneuvering close to the ground. In fact, a quick and dirty search of the NTSB’s aviation accident database for events involving single-engine airplanes and the string “simulated engine failure” occurring between January 1, 2016, and July 1, 2020, returned 21 accidents, two of them fatal. All sorts of mishaps befell the pilots involved, from hard landings to actual engine failure, perhaps from carburetor ice. Airplanes involved ranged from an Aeronca 7AC Champ to a Cirrus SR22 (one of the fatals).

The one time (so far) I’ve needed to use the skills learned in engine-out drills, everything turned out about as well as could be expected. I was flying my Debonair, with a pilot and A&P in the right seat and another pilot in one of the rear seats. We had taken off with full tanks and were near gross weight. I had just completed a cruise climb to 9000 feet msl, a few miles southwest of Jacksonville, Florida, when the engine went from smooth to very rough, with a corresponding power loss. The engine monitor showed one cylinder bank’s EGTs remaining relatively steady and the other randomly dancing around.

I did all the remedial actions—including switching tanks and turning on the electric fuel pump—to no avail and let the airplane decelerate at altitude before punching off the autopilot and altitude hold, then slowing further to the airplane’s best glide speed. We were IFR but in severe clear weather and talking to Jacksonville Approach, whom I promptly advised of the problem. By the time I told the controller I was declaring an emergency and requesting a vector to the nearest airport, I had lowered the nose enough that I could see four big, beautiful runways a few miles in front of me. It was the former Cecil Naval Air Station, now Cecil Airport (KVQQ), sporting a 12,500-foot-long Runway 18L/36R. From where we were, a well-fed Border Collie could have successfully landed at Cecil.

After finding a power setting that resulted in the least vibration, we slowly descended toward Cecil. Surface wind was out of the west, and Runway 9R/27L offers 8000 feet of U.S. Navy-approved concrete, so that’s the runway I set up for. Arriving at the key position—abeam the runway numbers—I had way too much altitude, and that’s when I violated a guideline about engine-out landings: don’t turn away from the landing area. I wasn’t about to extend the downwind leg, and S-turns weren’t going to work, so to lose altitude I ended up making two standard-rate 360-degree turns while maintaining best glide. Rolling out of the second one, I was at about 1500 feet agl and proceeded around the traffic pattern, saving the flaps and gear until I had the runway made.

We touched down about a third of the way down the runway and turned off before reaching the last third, then managed to taxi to the ramp under our own power and the watchful eye of the airport’s CFR equipment. After shutting down, it didn’t take long for the A&P who had been in the right seat to diagnose a cracked cylinder and broken valve had led to all sorts of mischief.

The punchline? My training worked. Yours will, too.

RUN A CHECKLIST?

One of the reasons we practice engine-out drills is because when we’re trying to restart the engine is not the best time to pull out a checklist and try to read it. Instead, we use the drill to develop enough understanding of the remedial actions that we automagically perform them when called upon. These memory items can include checking the magnetos, power settings, carb heat, fuel selector, fuel pump and other controls that may get the engine running again.

If nothing works to restore power, you’ve already identified and are maneuvering toward a landing area, and there’s enough altitude/time, then you can pull out the emergency checklist. It should be readily available in the cockpit and you should already be familiar with which page you want, and how to find it.

Start at the top and perform each checklist item in the order presented, even if you “know” you’ve already accomplished that step. Have a passenger read it to you if one is available. If all that fails, then turn to the power-off, emergency or off-airport landing checklist and start running through those items.

Figuring out where to land is a significant part of the simulated engine-out drill. It needs to be long enough and sufficiently free of obstacles that a successful off-airport landing is plausible, and be within gliding range.

The worst-case scenario is at low altitude shortly after takeoff. Our January 2006 issue and the article “Turnbacks Reconsidered” concluded a straight-ahead landing is “the best low-risk option.”

When time and altitude permit, a runway is always the best choice. Many pilots, myself included, are chagrined to learn we never saw a suitable one was underneath us or off the right side when the instructor announced the drill. The moral is to look down, look right and look behind you for the nearest runway or landing area.

Some popular EFB apps have a feature that plots gliding range on the underlying moving map, resolving the question of whether you can reach a depicted runway

For purposes of the drill in training, it may not matter if you overlooked a nearby runway. On the checkride and in real life, it may.

POWER-OFF APPROACHES

Flying the power-off approach to a confined area is a gold-standard airmanship test, and the only way to perfect it is with practice. The good news is you can practice power-off approaches, and their variations, with a perfectly good airplane, all by yourself.

There are three basic variations. One is to close the throttle at the key position abeam the runway numbers and fly a tighter standard pattern. The spiraling approach allows shedding excess altitude over the key position until you can fly the tight pattern. The third is a straight-in from some distance and altitude away. All of these variations have their own gotchas, which demand practice and honest assessments of the outcomes.

The engine-out drill can be challenging but it can also be a lot of fun. Once you’re committed to making an off-airport landing, you use the remaining energy (altitude) and drag devices (flaps, spoilers and/or landing gear) to put the airplane on a predetermined spot at touchdown speed. What could be a more gratifying test of your airmanship than that?

Jeb:

Nice article. Thanks. I missed reading that issue of Aviation Safety. My bad!

So, the NTSB aviation accident DB had about included about 4 engine fail simulations annually that turned into accidents over 4 1/2 years. That’s a good cautionary number for CFI’s and individual pilots who are practicing for the real thing.

An equally interesting event you mentioned was your diversion to KQVV. Note that No Accident =>> NO NTSB or FAA Record. Between 2014 and 2015 I did a little survey of pilots who experienced one or more losses of power for any reason while flying a single engine, piston engine, aircraft built by any factory putting out production aircraft. Note, “Survey” means that ‘stats’ are just a rough idea of reality, i.e. self reporting introduces a bit of bias, AND dead pilots don’t respond to surveys after their accidents… The results were interesting, and very encouraging. The ratio of pilots who experienced a total loss of power and who managed to land without an accident that met the NTSB 830 definition of a reportable event was about 4:1. I.e., 80% of responding pilots who had a dead engine landed with a reuseable airplane, and occupants (themselves included) suffered no physical harm. If the engine still produced partial power the odds of a no harm, no report outcome were about 30:1. Over 1,000 respondents provided their input. Respondents ranged from 10 hour students to a couple of 30,000 pros. Average logged flight hours between loss of power events that caused an unwanted landing (off airport, or an ‘impossible turn’) for the subset of pilots who self reported those events in aircraft that met the criteria was around 2,000 hours. My take is that skill is important – and the majority of pilots were skillful. And that LUCK is also important.

I did the flight review for the pilot of the Mooney M20 pictured with this article. He had recently purchased the aircraft and did it seemed that he did not have much of a checkout. We did no less than 3 simulated engine outs during the flight review after we botched the first one . The last one to a landing on a 2100′ strip. It apparently paid off as he texted me after landing on the golf course after a catastrophic engine failure. Practice , Practice and more Practice…..and if circumstances permit ….fly it all the way to the ground. The last 500′ is where you earn your money.