The event perhaps most demonstrative of what can happen as an aircraft ages occurred on April 28, 1988, over Hawaii. That’s when an Aloha Airlines Boeing 737-200 operating in scheduled passenger service as Flight 243 between Hilo and Honolulu lost part of its cabin roof while in cruise at FL240. The crew successfully landed the airplane after diverting to Maui. Of the 89 passengers and six crewmembers aboard, there was one fatality—a flight attendant who was swept overboard during the decompression event.

Seven passengers and another flight attendant sustained serious injuries. The photo below, taken shortly after the 737 landed in Maui, shows the damage to the airplane and the passengers’ exposure. According to the NTSB, “Approximately 18 feet from the cabin skin and structure aft of the cabin entrance door and above the passenger floor line separated from the airplane during flight.”

The NTSB’s probable cause finding focused on inadequate maintenance by the carrier and production difficulties encountered by Boeing with its cold bond lap joint construction method. According to the NTSB, Aloha failed to detect significant disbonding and fatigue damage in the fuselage skin, and the FAA failed to include all potentially defective lap joints in a related airworthiness directive it developed from a Boeing service bulletin. The salt air of the airplane’s operating environment, plus the accelerated number of pressurization cycles it had experienced flying the carrier’s relatively short routes, had promoted corrosion and what the NTSB labeled “premature fatigue cracking,” leading to the failure.

Not Just Jets

Fast-forward to just the last 18 months. In April 2018, a Piper PA-28R-201 Arrow V lost its left wing shortly after takeoff from Daytona Beach, Fla. Both the commercial-pilot applicant and the ATP-rated designated pilot examiner were killed. At this writing, the NTSB has not yet issued a probable cause finding, but its preliminary report notes that “examination of the left wing main spar revealed that more than 80% of the lower spar cap and portions of the forward and aft spar web doublers exhibited fracture features consistent with metal fatigue.” The airplane was manufactured in 2007, and had accumulated 7690.6 hours of flight time. In December 2018, the FAA proposed an airworthiness directive requiring inspection of the wing spars on Piper PA-28 and PA-32 airplanes with a certain factored time-in-service.

Meanwhile and beginning in late 2018, concern arose in the Beechcraft Bonanza/Baron/Debonair community about control cable failures. A number of the airplanes’ control cable turnbuckle assembly shanks were found with cracks and corrosion where required safety wire had trapped moisture and other material for years. The turnbuckle assemblies are used on aileron, elevator and trim cables in aircraft manufactured in the 1960s and 1970s. Later airplanes use a different security scheme, with clips instead of safety wire. Textron—Beech’s newest owner—the American Bonanza Society type club and the FAA all have released detailed information and recommendations on the problem. See the sidebar above for more details.

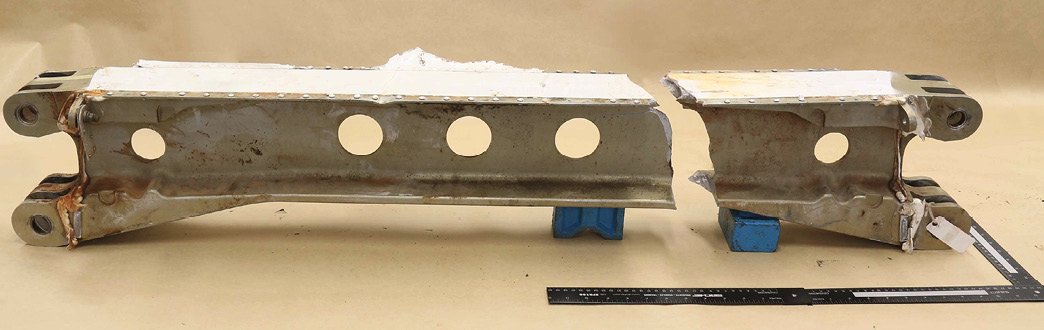

On May 26, 2019, a Cessna T210M Turbo Centurion II being operated as a geological survey flight crashed in Queensland, Australia, after its “right wing separated, resulting in a rapid loss of control and subsequent collision with terrain,” according to the Australian Transport Safety Bureau (ATSB). Both pilots aboard died and the airplane was destroyed. The airplane was manufactured in 1976 and had accumulated 12,174 total flight hours at the time of the accident. Also according to the ATSB, the T210’s wing spar carry-through structure had “fractured through an area of pre-existing fatigue cracking” located inboard of the wing attachment lugs. An image of the failed carry-through is below, courtesy of the ATSB, whose investigation continues.

Common Factors

If you’ve read this far, you’ve probably figured out by now that corrosion, cracks and metal fatigue are primary factors in these failures. The age and flight time of the aircraft involved, and how the aircraft are used, also figure prominently.

For example, the Piper Arrow that lost a wing was operated by Embry-Riddle Aeronautical University as a trainer at the institution’s Florida campus, where—like the Aloha 737—it spent a lot of time in salt air. For its last six years and some 6000 flight hours, the 43-year-old Australian T210 had been operated in the geological survey role, which typically involves higher operating weights, 140-150 knot airspeeds and the low-level maneuvering required to follow the survey area’s topography. All of the Beechcraft models addressed are at least as old as the Australian T210.

It’s likely you own or fly an aircraft of similar vintage, but perhaps not one dedicated to full-time training or specialized operations. The FAA’s Special Airworthiness Information Bulletin (SAIB CE-19-13) responding to the Beechcraft control cable findings specifically noted that the turnbuckles like those on the affected fleet “are widely used in flight control systems on a multitude of airplane models that utilize mechanical flight control cables.”

What to do

In our view, these recent events highlight the need to consider how your airplane is inspected and maintained, plus how it’s flown. If it has been or will be operated regularly in a salt environment, you may wish to adopt an increased inspection frequency or prophylactically replace/overhaul certain critical components on shorter schedules than originally recommended. Targeted corrosion control—especially of metal wing spars—and closer, more detailed examination of critical structures and assemblies during scheduled inspections—like control cable turnbuckles—should be a no-brainer, along with a hangar.

Finally, how we operate aging airplanes is another consideration. It’s one thing for a 60-year-old airplane to spend all day in cruising flight. It’s quite another for it to be used in primary training, aerobatics or in any kind of high-activity commercial operation. We’d also want to be way below the appropriate turbulence-penetration airspeed in the bumps and make gentle landings.

Beech Control Cable Turnbuckles

According to the American Bonanza Society (ABS), there have been at least six recent cases of failure of the swaged end of flight control cables at the turnbuckles in Beech piston-powered airplanes. Aileron, elevator and rudder control cables have been involved, and the NTSB is investigating at least two failures.

All failures resulted from corrosion of the swaged end of the cable in turnbuckles beneath heater ducts (aileron cables) or fresh air inlets (rudder and elevator cables). The ABS also received mechanic’s reports regarding cables and turnbuckles in these areas that were wet from condensation but did not yet exhibit corrosion.

Required safety wire in these installations both prevents visual inspection and tends to trap moisture and debris, potentially accelerating corrosion. According to the ABS, safety wire must be removed to inspect for this type of damage. In two instances, the swaged cable ends failed and “the safety wire was all that was holding it together.” The images here are from the FAA.

Best Practices For Maintaining Aging Aircraft

It’s been 16 years since the FAA and industry groups developed the “Best Practices Guide for Maintaining Aging General Aviation Airplanes,” but its contents are still valuable. Some examples of the Guide’s recommended best practices in these areas include:

Airplane Records Research

• Aircraft logbooks and FAA Records: Logbooks should be examined for missing entries and for a record of missing equipment. Obtaining the FAA’s records may help clarify the airplane’s status.

• Type Certificate Data Sheet: The TCDS includes a summary of the baseline technical description of the type’s performance, weights, CG limits and more.

• Airworthiness Records: These include airworthiness directives (ADs), Special Airworthiness Information Bulletins (SAIBs), manufacturer service bulletins, FAA service difficulty reports (SDRs) and any supplemental type certificates (STCs).

Special-Attention Inspections

• According to the Guide, “A detailed inspection or series of inspections, modifications, parts replacements, or a combination of these may be necessary to keep an aging airplane operating safely.”

• Fortunately, system design concepts “are similar from model to model and from manufacturer to manufacturer for most aging GA airplanes,” according to the Guide.

When aircraft like this early Cessna 172 are stored outside in the weather, they likely will require a greater emphasis on maintenance items like corrosion control. Avionics, paint and interior appointments are not the only casualties of storing an airplane outside on a tiedown.