Those of us flying aircraft with reciprocating engines should be performing what is commonly referred to as a mag check, or magneto check, prior to every flight. During the engine run-up, we turn the ignition key to the Left position to disengage or ground the right magneto, noting the rpm change, before turning the key back to Both. We then repeat this process by turning the key to Right to ground the left magneto. 288 In addition to noting the rpm drop, if any, we also should be examining other instrument indications-fuel flow, if so equipped-and especially, the EGT values presented on a multi-probe engine monitor if one is installed. But how many of us really understand whats being tested, why its being tested and what it means to the safety of our flight if the check fails? Is an rpm drop, by itself and within spec, all we need to see to ensure our airplanes ignition system is healthy? RPM Drops and Fouling The primary indication a magneto is properly grounded is an rpm drop. Thats because only half of the spark plugs (one of the two on each cylinder) are receiving electrical current from the magneto. We want to confirm the engine will keep running on just one magneto, which is supposed to provide enough power to get us safely to the nearest airport. If the rpm drop is greater than suggested by the airplane flight manual or pilots operating handbook, a couple of things can be wrong. Most likely is that one or more of the spark plugs for which the selected magneto supplies power is fouled with carbon, fuel or oil deposits and not firing. Spark plug fouling can occur when the mixture is too rich for a given operation, typically with the engine idling on the ground on a hot summer day or at high altitude, when incomplete combustion can occur. We may observe the engine running rough on one magneto. This can usually be relieved by returning the ignition to Both and increasing power for a few minutes with the mixture leaned to heat up the cylinders and burn off any deposits that may have accumulated on the spark plugs-kind of like a self-cleaning oven. Then repeat the magneto check. If the engine is still running rough, it may be lead or oil thats stuck to the spark plugs, and the engine will not be able to produce enough heat to remove the buildup. In this instance, the spark plugs must be removed and cleaned or replaced. While a Private pilot may legally do this, FBOs usually consider it a

One of the best ways to prevent spark plug fouling is to lean the engine properly during ground operations. This may go against what your primary instructor told you early in your training. By suggesting you leave the red knob in the full-rich position while taxiing, he or she was probably more worried about you taking off without fully enrichening the mixture. Preventing that occurrence is why we have pre-takeoff checklists.

If the rpm drop is greater than recommended, its also possible the grounded magneto is improperly timed. In other words, the grounded magneto is not causing the spark plugs to fire at the peak of the cylinders ignition cycle, so it isnt producing as much power as it was supposed to in the first place. When you take it out of the equation by turning the ignition key to select the other magneto, the rpm is not much lower than what it was with both magnetos engaged.

Hot Mag? Cool Your Heels

But what if you turn the key to Right or Left and observe no change in rpm at all? The magneto not selected by the switch is actually still firing its spark plugs-the connection is hot, indicating the magnetos P-lead, or grounding wire, is not properly connected.

Recently, I discovered a hot magneto in our clubs Cessna 182S Skylane during the run-up and chose not to fly the plane. During the run-up, when I turned the switch to Right, there was no drop in rpm at all and when I turned the key to Off, the engine kept running just the same. In the unlikely event I needed to shut down the engine in flight (due to a fire or forced landing) this could make it more difficult.

Also, how could I know why the magneto was hot? Was it the ignition switch or the P-lead that was broken? What if a wire connection was loose somewhere and full-throttle engine vibration on takeoff caused it to shift position? I could lose some or all engine power at a critical time. I decided that flying the plane in that condition was not worth the risk, especially since I was not sure what was causing the problem.

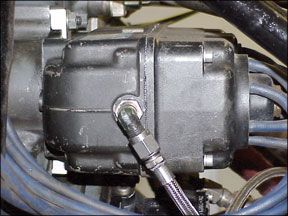

A few weeks later, I spoke about the situation with William Hughes, the mechanic who performed the repair to the Skylane. Hughes is the chief of maintenance at Montgomery Aviation in Gaithersburg, Md., where the plane is based. He said that the problem I experienced probably would not have caused any hazard to my flight after all, because the connector inside the magneto to which the P-lead attaches had completely broken off. No matter what position the ignition key was in, that magneto was stuck in the On position because the grounding wire could not make contact with it. But at the time, I had no way of knowing that, and still feel I made the right decision not to fly.

“It just meant that mag would keep firing its plugs as long as the prop was turning,” Hughes said. “There was no way that mag would have grounded out. It was an actual break that would not have re-secured itself. But it would have produced a hazard on the ground.”

In 1977 the FAA issued Airworthiness Directive AD 76-07-12 requiring all aircraft using magnetos with certain Bendix ignition switches be tested for proper grounding function every 100 hours. The AD states, “With the engine at normal idle, rotate the switch key or lever through the Off detent to the extreme limit of its travel in the Off direction. If the engine stops firing, this indicates an airworthy switch.”

Many affected aircraft may have had their ignition switches replaced, though the FAA subsequently issued a similar AD in 1994 affecting certain Teledyne Continental Motors (TCM, formerly Bendix) magnetos. However, pilots still perform this check prior to engine shutdown because it is a foolproof way of ensuring that both magnetos truly are grounded when the ignition switch is in the Off position.

The Off position mechanically causes both the Right and Left magneto P-leads to engage, grounding both magnetos at the same time. But what if the switch is broken and the Off position doesnt ground the mags? Its possible the magnetos may ground independently during the run-up check but that one or both of them could still be “live” with the ignition in the Off position at shutdown.

Grounding Check

As a Student pilot, I was taught to do a grounding check at shutdown to ensure that when and if I needed to move the propeller by hand (for instance, to attach the tow bar) I wouldnt accidentally start the engine and make salsa out of myself. I did this test faithfully for a while, but after several loud, hair-raising backfires that resulted from me fumbling to get the ignition key quickly back to Both from the Off position before the engine quit, the procedure faded from my repertoire. I started to wonder if I was doing more harm than good. Besides, I was very careful not to move the propeller too much, avoiding the telltale click of the impulse coupling-a wound-up spring that, when let go, snaps the magneto into action and generates a spark that, if the correct fuel-air mixture is present in one or more cylinders, could cause ignition. But how could the engine start if Id shut it down by pulling the mixture to idle cutoff?

After my recent hot magneto discovery and subsequent conversation with several mechanics, Ive decided to revise my engine shutdown checklist.

“Once you shut the engine off with the mixture, you may not have completely shut off the fuel flow,” Hughes advised. “What youve done is reduced the fuel flow to the point where whatever was going into the engine was not sufficient to support combustion. With Cessnas [and other aircraft whose fuel tanks are above the engine -Ed.], that fuel system has constant gravity pressure trying to feed fuel to the engine. If the mixture is not fully shut off, fuel can seep past the seals and enter the cylinders or get into the carburetor area, in sufficient quantity that if there is an ignition or compression source it could start the engine.”

A query of the NTSBs online database for events involving a “hot mag” or “hot magneto” returned just one hit in the last 20 years, though presumably many unintentional engine starts that do not result in injury or damage go unreported. On May 15, 1991, the pilot of a Cessna Model 177 Cardinal in Greensboro, N.C., noticed during engine start that the starter was operating but not engaging the engine.

“He turned off the magnetos and battery and exited the airplane to investigate,” the report states. “He did not chock or secure the airplane. He turned the propeller some, then began to walk away. The engine then roared to life. The airplane proceeded across the ramp and collided with a parked Beech Model 77 Skipper. An inspection of the airplane revealed that the left mag would not ground out with the switch, resulting in a hot mag condition.”

Some pilots try to avoid this situation by moving the propeller backward (clockwise as you are facing it from the outside). While doing so will prevent the impulse coupling from winding up and snapping, Hughes cautioned doing so could damage vanes in the engine-driven vacuum pump, especially if its a dry pump. “Any groove or nicks on the housing can chip the edges of those veins and reduce their efficiency and set up a situation where theyll self destruct,” Hughes said.

What If It Backfires?

Once I convinced myself that doing a magneto grounding check prior to engine shutdown is a good idea, I still wondered about the risks associated with bungling it and causing a backfire.

“The risk of fire is small because theres so little fuel going into the engine,” Hughes advised. “Most of what you hear as the backfire is not coming through the carburetor. When you shut the engine off with the prop turning, all of your normal ignition cycles are occurring except combustion, so when the ignition fires again the cylinder is operating normally but on the first exhaust stroke you have a flame going into the exhaust system and it can literally blow up a muffler. Thats the most likely damage.”

Despite being dated technology, magnetos do their job with relatively good efficiency and little fuss. Understanding that little mag switch is an important part of your engines ignition system and knowing how it works, and what its proper manipulation can tell you, can be invaluable to ensuring the safety and efficiency of your airplanes engine. Just remember these basic tips for conducting magneto and ignition switch checks-and check to ensure the mags are grounded.

Meredith Saini is a freelance aviation writer and flight instructor flying from the Gaithersburg, Md., area.