Beechcraft S35 Bonanza

Cracked and Corroded

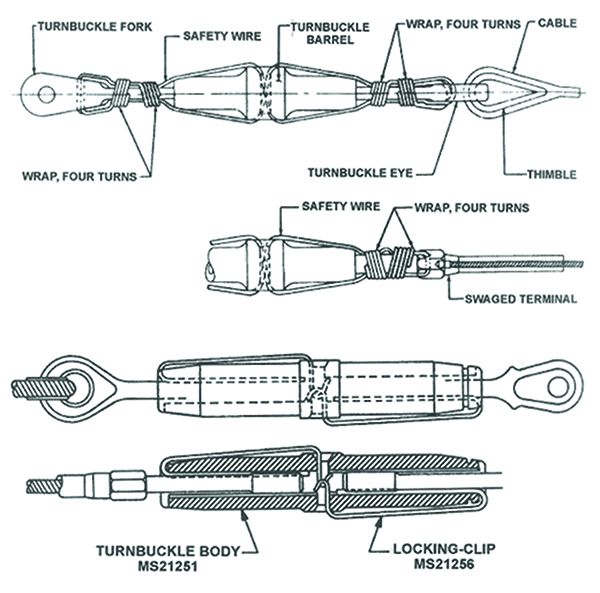

During an annual inspection, discovered right lower aileron control cable turnbuckle barrel located under aft cabin heat duct was cracked ¾ inches longitudinally from its end. The heating system duct above this turnbuckle assembly was in a decayed condition. Recommend close inspection of cables and turnbuckles in this area.

Part total time: 3875.0 hours

Beechcraft S35 Bonanza

More Cracked and Corroded

At the owner’s request, we removed the seats and floorboards to inspect the aileron cable turnbuckle. The turnbuckle (p/n AN-155-32S) was corroded under the safety wire. When the safety wire was cut, the turnbuckle failed. The safety wire was the only component holding the turnbuckle together. This turnbuckle is located under the rear heater hose fitting and appears to have collected moisture, which then dripped down onto the turnbuckle. Recommend removing the safety wire to properly inspect.

Part total time: Unknown

Cessna 172G Skyhawk

Control Cable Separation

Aircraft lost aileron control in flight. Pilot declared emergency and landed. The left aileron’s swaged turnbuckle fitting under right side of the cockpit panel had failed.

Part total time: 5228.0 hours

Cessna 182Q Skylane

Corroded And Pitted

During an annual inspection, we found the left forward and aft aileron turnbuckle ends (p/n MS21252-511) corroded and pitted. Installed new turnbuckle ends and rigged per Cessna maintenance manual.

Part total time: Unknown

Piper PA-28-180 Cherokee 180

Cracked Cable Swaging

While retensioning the lower stabilator turnbuckle after stabilator replacement, the aft cable end appeared bent. Inspection showed a crack and partial parting of the swaged cable end. The crack was between the threads and safety wire hole in the area where the safety wire wraps to the end and would have been concealed by the safety wire.

Part total time: 3851.0 hours

Piper PA-28-235 Cherokee 235

More Cracked Cable Swages

While accomplishing AD 2013-02-13 for stabilator cable turnbuckle and swaged fitting corrosion, discovered that the brass turnbuckle was badly corroded and needed replacement. While inspecting the stainless steel swaged fittings, discovered a crack in the lower aft stabilator cable that ran approximately halfway around the fitting.

Part total time: 1029.0 hours