Beech B55 Baron Disintegrating Fuel Cell Foam

Prior to installing an overhauled fuel cell, it was found to contain a large quantity of sawdust-like particles. Further inspection revealed the foam filling the fuel reservoir was breaking down. The older cells reservoir foam insert was compatible with 100/130 fuel. However, 100LL causes the foam to break down into fine particles that get trapped in filters and screens. This problem is addressed in service bulletin (SB) number 2109 which replaces the old style foam (p/n 369200157) with a product that is suitable for use with 100LL.

Part Total Time: 2616.0 hours.

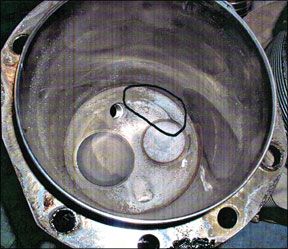

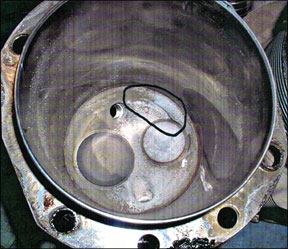

Superior

Cracked Cylinders

A technician found both the number 3 and 4 cylinders with visible cracks originating

288

at the exhaust valve seat. The engine is a Continental IO-520-F powering a Cessna U206F, Superior p/n SA52006-A20P.

Part Total Time: 847.9 hours.

Cessna 150/152

Cracked Aft Fin Attach Fittings

An analysis of the FAAs Service Difficulty Report (SDR) database reveals 41 reports of cracks in the aft fin attach fittings on Cessna 150/152 airplanes, p/n 0431009. There are three dash numbers: -1, -2, and -3. Most of the reports have been the -3 part. The SDRs are for cracked, broken or corroded attach fittings.

Further, analysis of the SDR data indicates the problem was getting worse from 1976 through 1991. Since 1992, these analyses indicate improvement, with SDRs reported less frequently, due to the awareness of maintenance technicians to this problem. However, since the Cessna 150/152 airplanes are used for training, aerobatics and spins, which place additional loads on the vertical tail surface, the FAA wants technicians, owners and operators to remain aware of the problem.

Continental IO-240-B17B

Jammed Fuel Pump Shaft; ATA 7314

The mixture control shaft on the engine driven fuel pump froze halfway between full rich and idle cut-off. This created a lean mixture. The mixture control was (first) disconnected from the fuel pump, then the fuel pump control shaft had to be freed up. The mixture cable was completely free (with no binding) once disconnected from the fuel pump (p/n 649368-49A1), which was replaced and sent back to the factory.

Part Total Time: 380.4 hours.